Special Vehicles

- Aerial platform truck

- Dolly Trailer

- ISO Tank

- Recovery Trucks

- Road Sweeper

- SKD Truck Body

- Special Vehicle

- Tank Trailer

- Tank Truck

- Truck Accessories Parts

- All Wheel Drive off road truck

- Beiben truck Customizing

- Body parts

- Concrete mixer trucks

- Crane truck

- Environmental Trucks

- Fire Trucks

- ISUZU UD HINO Truck Customizing

- IVECO FOTON-FAW JAC Customizing

- Portable Tank Container

- Recovery Trucks Wrecker

- Road tanker

- SHACMAN Truck Customizing

- Special Car

- storage tank

- Machinery

- PPE

Wechat: +8615271357675

MOB: 86-152-71357675

ADD: NO.1 TAIZONG AVENUE GAOQIAO INDUSTRY PARK TAIWANESE INVESTMENT AREA DONGXIHU DISTRICT WUHAN CITY, HUBEI PROVINCE, P.R CHINA

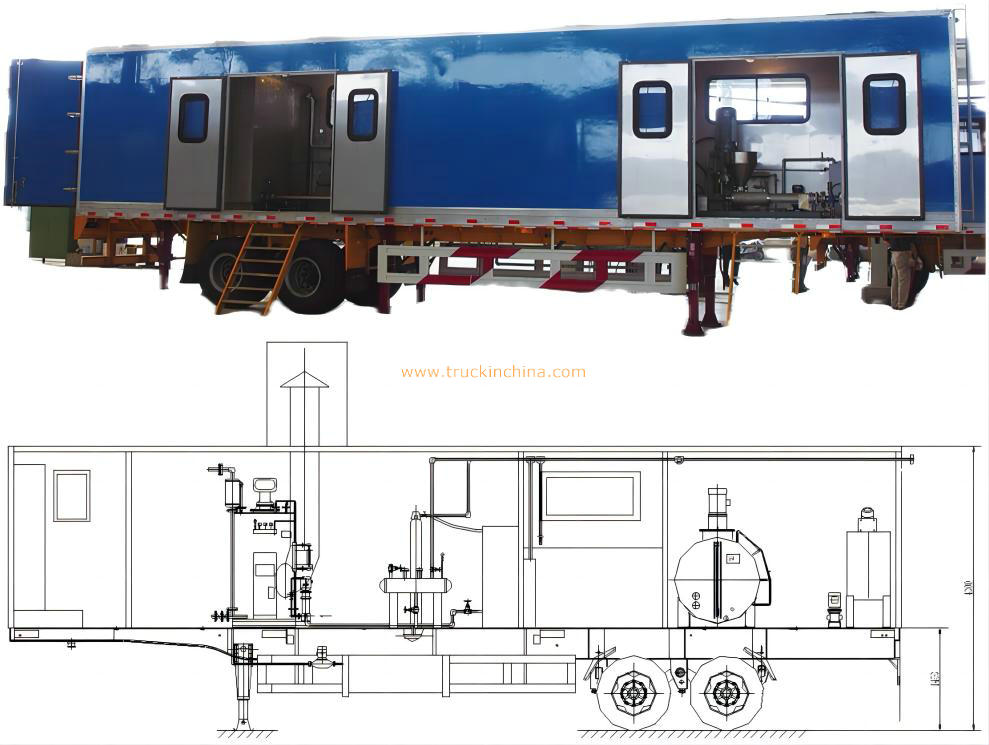

Customize Mobile Portable Modular ANFO Emulsion Explosive Plant (Trailer Mounted)

ANFO Mix Modules and Units | Explosive Equipment

Portable Modular Emulsion Plants capacity: 5000 tons of bulk emulsion explosive,

1000 tons of finished emulsion explosive

Price for refer only. Final Price Offer Discount.

| Availability: | |

|---|---|

| Quantity: | |

|

| |

-

MKH

-

-

-

China

-

-

T/T

-

1

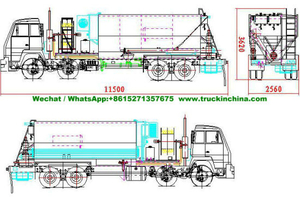

Customize Mobile Modular ANFO Emulsion Explosive Plant ( Trailer Mounted)

Production capacity

The production capacity has the following series:

performance parameter:

Annual output (t): 4000,6000,8000,10000

Total installed power: 85 kW-125 kW

Bulk emulsification efficiency: 8-18t / h

Emulsification efficiency of finished emulsion explosive (drug roll): 1-5t / h

ANFO Mix Modules and Units | Explosive Equipment

All the equipment implements the digital control, and the key process has the safety chain function.4000 tons / year; 6000 tons / year; see Table 1. For 8000 tons / year; 10000 tons / year; the above annual production capacity can be met by increasing the tank quantity or changing the tank storage capacity.

Process introduction

1. Production program

Annual output of 3000 tons of field mixed emulsion explosive, 1000 tons of finished emulsion explosive

(The actual production capacity is greater than 5,000 tons)

Work system and production capacity

Work system: work class system; one shift system

Working hours; 8 hours working (7.5 hours effective hours)

Working day: 250 days

Production capacity: 5000 tons of bulk emulsion explosive, 1000 tons of finished emulsion explosive (single shift) (the actual production capacity is more than 5000 tons)

Variety: (1) open-air emulsion explosives (on-site mixing) (2) finished emulsion explosives (small medicine roll)

One production line is arranged in parallel, which can meet the loading operation of two units, mixed vehicles. The production capacity of bulk explosives in each production line is 12-18 tons / hour. The finished explosives (small rolls) produced by each production line is 5-7 tons / hour

Portable Modular Emulsion Plants

Portable Modular Emulsion Plants is represented by processing equipment, put in modules, having dimensions of standard 40-foot containers with separate location of the main unit (production of the emulsion matrix) and the unit for the preparation of a gas-generating agent.Allows you to move production quickly to another facility 1 day installation. From greenfield to emulsion production It does not need capital construction and connection to general utilities It is suitable for small scale production and service providers

1 | Emulsion matrix density | 1.35-1.45g/cm3 |

2 | The ation speed of the product after sensitization | 4200 m/s (tested in Φ150mm PVC tube) |

Material name | scale (%) |

ammonium nitrate | 65~85 |

monarkite | 0~14 |

water | 9~12 |

emulsifier | 2~2.5 |

Composite wax | 4~4.5 |

Flame remover (coal mine allowable type) | 4~8 |

Table 3-1 Table Of Process Equipment For The Production Line | ||||||

Order Number | Device Name | Unit | Quantity | Plant Capacity (Kw) | Material Quality | |

Light Engine | Amount To | |||||

1 | Crusher | Set 、Pcs | 1 | 15 | 15 | Stainless Steel |

2 | Screw Conveyer | Set 、Pcs | 2 | 5.5 | 5.5 | Stainless Steel |

3 | Water Phase Soluble Tank | Set 、Pcs | 2 | 7.5 | 7.5 | Stainless Steel |

4 | Water Storage Tank | Set 、Pcs | 1 | 5.5 | 5.5 | Stainless Steel |

5 | Water Phase Filter | Set 、Pcs | 2 | Stainless Steel | ||

6 | Oil Phase Soluble Tank | Set 、Pcs | 2 | 5.5 | 5.5 | Stainless Steel |

7 | Oil Phase Storage Tank | Set 、Pcs | 1 | 5.5 | 5.5 | Stainless Steel |

8 | Oil Phase Filter | Set 、Pcs | 2 | Stainless Steel | ||

9 | Water Matching Ratio Pump | Set 、Pcs | 1 | 3 | 3 | Stainless Steel |

10 | Oil Matching Ratio Pump | Set 、Pcs | 1 | 1.5 | 1.5 | Stainless Steel |

11 | Water-Phase Flowmeter | Set 、Pcs | 1 | 0 | E+H | |

12 | Oil Phase Flowmeter | 1 | 0 | E+H | ||

13 | Static Mixer | Set | 1 | 0 | Stainless Steel | |

14 | Vincent's Allocator | Set | 1 | 0 | Stainless Steel | |

15 | Emulsifier | Set 、Pcs | 1 | 22 | 22 | Stainless Steel |

16 | Belt Cool Medicine Machine | Set 、Pcs | 1 | 6 | 6 | Stainless Steel Band |

17 | Continuous Sensitizer | Set | 1 | 15 | 15 | Stainless Steel |

18 | Pharmacy Filling Machine | Set 、Pcs | 2 | 0.37 | 0.74 | Stainless Steel |

19 | Pharmacy Storage Tank | Set 、Pcs | 2 | 0 | Stainless Steel | |

20 | Material Pipeline System | Set | 1 | 0 | Stainless Steel | |

21 | Delivery Belt Machine | Set 、Pcs | 1 | 4 | 4 | Stainless Steel |

22 | Large Drug Repelling Machine | Set 、Pcs | 1 | 10 | 20 | Stainless Steel |

23 | Drug Roll Belt Machine | Set 、Pcs | 1 | 4 | 4 | Stainless Steel |

24 | Bagging Machine | Set 、Pcs | 2 | 7.5 | 15 | Stainless Steel |

25 | Air Compressor | Set 、Pcs | 1 | |||

26 | Cooling Water Pump | Set 、Pcs | 1 | 7.5 | 7.5 | Steel |

EMULSION & MIX PLANTS

project | Emulsion metric | |||||||||

Rock emulsified explosives | Emulsified explosives are allowed in coal mines | Open-air emulsified explosives | ||||||||

No.1 | No.2 | one-level | two stage | three-level | Have detonator sensitivity | Lightless tube sensitivity | ||||

Drug roll density g/cm3 | 0.95~1.30 | 0.95~1.25 | 1.10~1.30 | — | ||||||

The explosive charge density is g/cm3 | 1.00~1.30 | 1.00~1.30 | 1.15~1.35 | 1.00~1.35 | ||||||

explosion velocity m/s | ≥4.5×103 | ≥3.2×103 | ≥3.0×103 | ≥3.0×103 | ≥2.8×103 | ≥3.0×103 | ≥3.5×103 | |||

brisance mm | ≥16 | ≥12 | ≥10 | ≥10 | ≥8 | ≥10 | — | |||

gap distance of sympathetic deto nation cm | ≥4 | ≥3 | ≥2 | ≥2 | 8≥ | ≥2 | — | |||

capacity for work mL | ≥320 | ≥260 | ≥220 | ≥220 | ≥210 | ≥240 | — | |||

Impact sensitivity | Exlast probability 8% | |||||||||

friction sensitivity | Exlast probability 8% | |||||||||

Hot sensitivity | No burning, no explosion | |||||||||

Toxic gas content L / kg after explosive explosion | ≤80 | — | ||||||||

Can gas safety | — | qualified | — | |||||||

Use guarantee period d | 180 | 120 | 120 | 15 | ||||||

Note: 1 The figures in the table are valid during the guarantee period, which is calculated from the date of explosive manufacture. 2 The explosive speed of the sensitive open-air emulsion explosive produced by mixed loading shall not be less than 4.2103m / s 3 For products with special requirements, their explosive performance can be determined by the supply and demand parties through negotiation. | ||||||||||

Ammonium Nitrate Emulsion Process Plants

Capacity / year | Soluble tank (m³) | Storage tank (m³) | Oil tank (m³) | Trace element box (m³) | crusher | emulsifier | On the screw | steam boiler |

4000t | 7 | 9 | 1 | 0.35 | PGC400 | RHQD10C | 6-8t/h | LSS0.5-1.0-Y |

6000t | 7 | 9 | 1.5 | 0.35 | PGC400 | RHQD10C | 6-8t/h | LSS0.5-1.0-Y |

8000t | 8 | 10 | 1.5 | 0.75 | PGC 500 | RHQD10C | 6-8t/h | LSS0.5-1.0-Y |

10000t | 10 | 12 | 2.5 | 0.85 | PGC 500 | RHQD10C | 6-8t/h | LSS0.5-1.0-Y |

Portable Modular Emulsion Plants allow us to respond to our customers’ need for high quality bulk emulsion on site, in remote locations where raw materials may be difficult to source

vehicle is equipped with water-phase preparation conveyer system, oil phase conveying system, vesicant conveying system, and emulsion conveying system. Motor car is provided with distribution panel, generator, steam boiler, surface water treatment plant, sewage treatment plant, and emulsifier storage in-sulation room etc.

Mobile ground station is endowed with advanced technology for power system, semi-finished product and raw material manufacturing and conveying etc, withsmooth process and stabile product quality, safe and reliable.

Customize Mobile Modular ANFO Emulsion Explosive Plant ( Trailer Mounted)

Production capacity

The production capacity has the following series:

performance parameter:

Annual output (t): 4000,6000,8000,10000

Total installed power: 85 kW-125 kW

Bulk emulsification efficiency: 8-18t / h

Emulsification efficiency of finished emulsion explosive (drug roll): 1-5t / h

ANFO Mix Modules and Units | Explosive Equipment

All the equipment implements the digital control, and the key process has the safety chain function.4000 tons / year; 6000 tons / year; see Table 1. For 8000 tons / year; 10000 tons / year; the above annual production capacity can be met by increasing the tank quantity or changing the tank storage capacity.

Process introduction

1. Production program

Annual output of 3000 tons of field mixed emulsion explosive, 1000 tons of finished emulsion explosive

(The actual production capacity is greater than 5,000 tons)

Work system and production capacity

Work system: work class system; one shift system

Working hours; 8 hours working (7.5 hours effective hours)

Working day: 250 days

Production capacity: 5000 tons of bulk emulsion explosive, 1000 tons of finished emulsion explosive (single shift) (the actual production capacity is more than 5000 tons)

Variety: (1) open-air emulsion explosives (on-site mixing) (2) finished emulsion explosives (small medicine roll)

One production line is arranged in parallel, which can meet the loading operation of two units, mixed vehicles. The production capacity of bulk explosives in each production line is 12-18 tons / hour. The finished explosives (small rolls) produced by each production line is 5-7 tons / hour

Portable Modular Emulsion Plants

Portable Modular Emulsion Plants is represented by processing equipment, put in modules, having dimensions of standard 40-foot containers with separate location of the main unit (production of the emulsion matrix) and the unit for the preparation of a gas-generating agent.Allows you to move production quickly to another facility 1 day installation. From greenfield to emulsion production It does not need capital construction and connection to general utilities It is suitable for small scale production and service providers

1 | Emulsion matrix density | 1.35-1.45g/cm3 |

2 | The ation speed of the product after sensitization | 4200 m/s (tested in Φ150mm PVC tube) |

Material name | scale (%) |

ammonium nitrate | 65~85 |

monarkite | 0~14 |

water | 9~12 |

emulsifier | 2~2.5 |

Composite wax | 4~4.5 |

Flame remover (coal mine allowable type) | 4~8 |

Table 3-1 Table Of Process Equipment For The Production Line | ||||||

Order Number | Device Name | Unit | Quantity | Plant Capacity (Kw) | Material Quality | |

Light Engine | Amount To | |||||

1 | Crusher | Set 、Pcs | 1 | 15 | 15 | Stainless Steel |

2 | Screw Conveyer | Set 、Pcs | 2 | 5.5 | 5.5 | Stainless Steel |

3 | Water Phase Soluble Tank | Set 、Pcs | 2 | 7.5 | 7.5 | Stainless Steel |

4 | Water Storage Tank | Set 、Pcs | 1 | 5.5 | 5.5 | Stainless Steel |

5 | Water Phase Filter | Set 、Pcs | 2 | Stainless Steel | ||

6 | Oil Phase Soluble Tank | Set 、Pcs | 2 | 5.5 | 5.5 | Stainless Steel |

7 | Oil Phase Storage Tank | Set 、Pcs | 1 | 5.5 | 5.5 | Stainless Steel |

8 | Oil Phase Filter | Set 、Pcs | 2 | Stainless Steel | ||

9 | Water Matching Ratio Pump | Set 、Pcs | 1 | 3 | 3 | Stainless Steel |

10 | Oil Matching Ratio Pump | Set 、Pcs | 1 | 1.5 | 1.5 | Stainless Steel |

11 | Water-Phase Flowmeter | Set 、Pcs | 1 | 0 | E+H | |

12 | Oil Phase Flowmeter | 1 | 0 | E+H | ||

13 | Static Mixer | Set | 1 | 0 | Stainless Steel | |

14 | Vincent's Allocator | Set | 1 | 0 | Stainless Steel | |

15 | Emulsifier | Set 、Pcs | 1 | 22 | 22 | Stainless Steel |

16 | Belt Cool Medicine Machine | Set 、Pcs | 1 | 6 | 6 | Stainless Steel Band |

17 | Continuous Sensitizer | Set | 1 | 15 | 15 | Stainless Steel |

18 | Pharmacy Filling Machine | Set 、Pcs | 2 | 0.37 | 0.74 | Stainless Steel |

19 | Pharmacy Storage Tank | Set 、Pcs | 2 | 0 | Stainless Steel | |

20 | Material Pipeline System | Set | 1 | 0 | Stainless Steel | |

21 | Delivery Belt Machine | Set 、Pcs | 1 | 4 | 4 | Stainless Steel |

22 | Large Drug Repelling Machine | Set 、Pcs | 1 | 10 | 20 | Stainless Steel |

23 | Drug Roll Belt Machine | Set 、Pcs | 1 | 4 | 4 | Stainless Steel |

24 | Bagging Machine | Set 、Pcs | 2 | 7.5 | 15 | Stainless Steel |

25 | Air Compressor | Set 、Pcs | 1 | |||

26 | Cooling Water Pump | Set 、Pcs | 1 | 7.5 | 7.5 | Steel |

EMULSION & MIX PLANTS

project | Emulsion metric | |||||||||

Rock emulsified explosives | Emulsified explosives are allowed in coal mines | Open-air emulsified explosives | ||||||||

No.1 | No.2 | one-level | two stage | three-level | Have detonator sensitivity | Lightless tube sensitivity | ||||

Drug roll density g/cm3 | 0.95~1.30 | 0.95~1.25 | 1.10~1.30 | — | ||||||

The explosive charge density is g/cm3 | 1.00~1.30 | 1.00~1.30 | 1.15~1.35 | 1.00~1.35 | ||||||

explosion velocity m/s | ≥4.5×103 | ≥3.2×103 | ≥3.0×103 | ≥3.0×103 | ≥2.8×103 | ≥3.0×103 | ≥3.5×103 | |||

brisance mm | ≥16 | ≥12 | ≥10 | ≥10 | ≥8 | ≥10 | — | |||

gap distance of sympathetic deto nation cm | ≥4 | ≥3 | ≥2 | ≥2 | 8≥ | ≥2 | — | |||

capacity for work mL | ≥320 | ≥260 | ≥220 | ≥220 | ≥210 | ≥240 | — | |||

Impact sensitivity | Exlast probability 8% | |||||||||

friction sensitivity | Exlast probability 8% | |||||||||

Hot sensitivity | No burning, no explosion | |||||||||

Toxic gas content L / kg after explosive explosion | ≤80 | — | ||||||||

Can gas safety | — | qualified | — | |||||||

Use guarantee period d | 180 | 120 | 120 | 15 | ||||||

Note: 1 The figures in the table are valid during the guarantee period, which is calculated from the date of explosive manufacture. 2 The explosive speed of the sensitive open-air emulsion explosive produced by mixed loading shall not be less than 4.2103m / s 3 For products with special requirements, their explosive performance can be determined by the supply and demand parties through negotiation. | ||||||||||

Ammonium Nitrate Emulsion Process Plants

Capacity / year | Soluble tank (m³) | Storage tank (m³) | Oil tank (m³) | Trace element box (m³) | crusher | emulsifier | On the screw | steam boiler |

4000t | 7 | 9 | 1 | 0.35 | PGC400 | RHQD10C | 6-8t/h | LSS0.5-1.0-Y |

6000t | 7 | 9 | 1.5 | 0.35 | PGC400 | RHQD10C | 6-8t/h | LSS0.5-1.0-Y |

8000t | 8 | 10 | 1.5 | 0.75 | PGC 500 | RHQD10C | 6-8t/h | LSS0.5-1.0-Y |

10000t | 10 | 12 | 2.5 | 0.85 | PGC 500 | RHQD10C | 6-8t/h | LSS0.5-1.0-Y |

Portable Modular Emulsion Plants allow us to respond to our customers’ need for high quality bulk emulsion on site, in remote locations where raw materials may be difficult to source

vehicle is equipped with water-phase preparation conveyer system, oil phase conveying system, vesicant conveying system, and emulsion conveying system. Motor car is provided with distribution panel, generator, steam boiler, surface water treatment plant, sewage treatment plant, and emulsifier storage in-sulation room etc.

Mobile ground station is endowed with advanced technology for power system, semi-finished product and raw material manufacturing and conveying etc, withsmooth process and stabile product quality, safe and reliable.

Related Products

SUCCESS CASES

More >>- 2026-02-013PCS T7 PE Lined ISO Tank Container for Potassium Hydroxide KOH, HCL Hydrochloric Acid, Hydrogen Peroxide for India

3PCS T7 PE Lined ISO Tank Container for Potassium Hydroxide KOH, HCL Hydrochloric Acid, Hydrogen Peroxide for India DTAU2601014 DTAU2601020 DTAU2601035 Vessel/Voyage:SHUN GANG CHANG JIE V.L2602E B/L Date: FEB. 01,2026 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2026-01-16T14 T7 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) , Potassium Hydroxide KOH, HCL Hydrochloric Acid, for India

T14 T7 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India DTAU2512010 DTAU2512025 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2025-12-1212KL Polyethylene PE Lined Tank Body for Hydrochloric Acid HCL Cargo Truck To Vietnam

12KL Polyethylene PE Lined Tank Body for Hydrochloric Acid HCL Cargo Truck To Vietnam

- 2025-11-11T7 T14 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India

T7 T14 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India DHF, HCL,KOH , H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide 20FT TANK CONTAINER (EMPTY AND NEW TANKS) DTAU2509090 DTAU2509103 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2025-09-28Advantages And Disadvantages of Different Material Storage T8 T14 PE / PTFE Lined ISO Tank Container for Electronic Grade Hydrogen Peroxide (H₂O₂) HCL,KOH

Advantages And Disadvantages of Different Material Storage T8 T14 PE / PTFE Lined ISO Tank Container for Electronic Grade Hydrogen Peroxide (H₂O₂) DTAU2509016 DTAU2509021 DTAU2509037

- 2025-09-016PCS T7 T14 PE Lined ISO Tank Container for HCL, PAC Hydrochloric Acid / Chemical Poly Aluminum Chloride 21KL To Vietnam

6PCS T7 T14 PE Lined ISO Tank Container for HCL, PAC Hydrochloric Acid / Chemical Poly Aluminum Chloride 21KL To Vietnam road transport type PE Lined Tank Used to contain: HCl , NaOH , PAC , H2SO4(max 98%) etc. Tank Capacity: 21,000 Liters 21m3 Steel sheet 6mm, head 6mm Liner thickness: 16mm PE 20 FT TANK (EMPTY AND NEW TANKS) HCDA2505016 HCDA2505021 HCDA2505037 HCDA2505042 HCDA2505058 HCDA2505063

- 2025-08-293 Units PE Lined T7 T8 T14 ISO Tank Container for DHF,HCL,KOH,H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide Export To India

3 Units PE Lined T7 T8 T14 ISO Tank Container for DHF,HCL,KOH,H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide Export To India DTAU2508010 DTAU2508025 DTAU2508030 20FT TANK CONTAINER (EMPTY AND NEW TANKS)

- 2025-06-1820PCS UN 3394 3399 Portable Tanks C-480 TMA Cylinders to USA

20PCS UN 3394 3399 Portable Tanks C-480 TMA Cylinders to USA PORTABLE TANK (EMPTY AND NEW TANKS) C-480 CYLINDER HS:860900.00(USA) Adr/Rid Organometallic Substance, Liquid, Water- Reactive C-480 Saddle Type Portable Tank, tank capacity 1880L KS1880-T21 Portable Tanks ASME Test DATA Report(C250051-C250070) BV Certificate No.:IIC-BVCT2570036S KSVU 250051 -70 Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg

- 2025-04-034 Units T14 ISO Tank Container PE Lined for Hydrofluoric HF Hydrochloric Acid HCL, Ferric Chloride Potassium Hydroxide KOH Tank Container Export To India

4 Units T14 ISO Tank Container PE Lined for Hydrofluoric HF Hydrochloric Acid HCL, Ferric Chloride Potassium Hydroxide KOH Tank Container Export To India DTAU2502011 DTAU2502027 DTAU2502032 DTAU2502048 20 FT TANK CONTAINER FOR HYDROCHLORIC ACID UN1789 HCL, HYDROFLUORIC ACID UN1790 HF ACID CARON STEEL AND LINED WITH 16MM LLDPE TANKS CAPACITY 21 KL FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, TOP UNLOADING TARE WEIGHT 5200KG 1UNIT 20FT TANK CONTAINER FOR UN1814 KOH POTASSIUM HYDROXIDE 45% SOLUTION DISH HEAD TYPE TANK CAPACITY: 19000LITERS FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, BOTTOM UNLOADING TARE WEIGHT 5300KG 1UNIT 20FT TANK CONTAINER FOR UN2014 H2O2 HYDROGEN PEROXIDE 31% SOLUTION DISH HEAD TYPE TANK CAPACITY: 19000LITERS FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, BOTTOM UNLOADING TARE WEIGHT 5300KG 2UNITS

- 2025-04-01Steel Lined PE Plastic ISO Tank for Hydrochloric Acid HCL12KL,15KL/16KL/19KL/22KL To Vietnam

Steel Lined PE Plastic ISO Tank for Hydrochloric Acid HCL12KL,15KL/16KL/19KL/22KL To Vietnam Description of goods Quantity N.W PE LINED STEEL TANK 5100X 2350 X 1400MM / 12.5M3 (EMPTY AND NEW TANKS) MODEL: DTA5212 HS CODE : 7309000000 、6300KGS PE LINED STEEL TANK 6040 X 2400 X 1600MM / 15.8M3 (EMPTY AND NEW TANKS) MODEL: DTA5215 HS CODE : 7309000000 1 3650KG PE LINED STEEL TANK 7190 X 2300X 1300MM / 16.2M3 (EMPTY AND NEW TANKS) MODEL: DTA5316 HS CODE : 7309000000 、4350KG PE LINED STEEL TANK 8520 X 2260 X 1350MM / 19.5M3 (EMPTY AND NEW TANKS) MODEL: DTA5319 HS CODE : 7309000000 、4850KG 20 FT TANK CONTAINER 6058X2438X2591MM / 22.8M3 (EMPTY AND NEW TANKS) MODEL: DTAU2501015 、5800KG

- 2025-02-261000L SS304 Stainless Steel Lined PE Plastic Tank for Hydrochloric Acid to GUAYAQUIL, EC

1000L SS304 Stainless Steel Lined PE Plastic Tank for Hydrochloric Acid to GUAYAQUIL, EC STORAGE TANK 304 STAINLESS STEEL LINED PLASTIC TANK VERTICAL TANK STAINLESS STEEL 304 THICKNESS 5MM+PE 16MM CAPACITY: 1,000 L RESIST 15%~38% HYDROCHLORIC ACID HS CODE:730900

- 2025-01-1920PCS Metal Alky TEAL C480 T21 UN Portable Tank Cylinders To USA

20Units UN T21 Portable Tank Container 1880L Cylinder For TEAL Metal Alkyls UN3394 UN3399 to USA with 30pcs Spare PSV RELIEF VALVES SF/A412F-25P(3B) Manufacturer (SHENYANG XINGUANG VALVE ) KS1880-T21 Portable Tanks Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg KSVU240016 -KSVU240035 Adr/Rid Organometallic Substance, Liquid, Water- Reactive C-480 Saddle Type Portable Tank, tank capacity 1880L

- 2024-12-206 Sets Thermal Insulated LLDPE Lined Tanks 25KL for Sodium Hypochlorite Hydrochloric Acid Storage Transport Tanker To Saudi Arabia

6 Sets Thermal Insulated LLDPE Lined Tanks 25KL for Sodium Hypochlorite Hydrochloric Acid To Saudi Arabia Lined PE Tanks 6604Gallon For Truck Trailer mounted FROM WUHAN PORT CHINA TO DAMMAM, SAUDI ARABIA BY SEA. + Port of loading : WUHAN PORT + Port of unloading :DAMMAM SAUDI ARABIA

- 2024-12-022 Units T14 Hydrofluoric Hydrochloric Acid UN1789 UN1790 ISOTank Container Road Transport For ASCOR

2 Units T14 Hydrofluoric Hydrochloric Acid UN1789 UN1790 ISOTank Container Road Transport For ASCOR 20FT Tank Container (EMPTY AND NEW TANKS) FOR HYDROCHLORIC ACID UN1789 HCL HYDROFLUORIC ACID HF ACID UN1790 CARBON STEEL AND LINED WITH 16MM LLDPE DTAU2404015, DTAU2404020

- 2024-10-245 Units C480 Keystone Vessel T21 TEAL Cylinder UN Portable Tanks To SAUDI ARABIA

5 Units Keystone Vessel T21 TEAL UN Portable Tank C480 Cylinder To SAUDI ARABIA KS1880-T21 Portable Tanks Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg KSVU2400114 KSVU2400120 KSVU2400135 KSVU2400140 KSVU2400156