Special Vehicles

- Aerial platform truck

- Dolly Trailer

- ISO Tank

- Recovery Trucks

- Road Sweeper

- SKD Truck Body

- Special Vehicle

- Tank Trailer

- Tank Truck

- Truck Accessories Parts

- All Wheel Drive off road truck

- Beiben truck Customizing

- Body parts

- Concrete mixer trucks

- Crane truck

- Environmental Trucks

- Fire Trucks

- ISUZU UD HINO Truck Customizing

- IVECO FOTON-FAW JAC Customizing

- Portable Tank Container

- Recovery Trucks Wrecker

- Road tanker

- SHACMAN Truck Customizing

- Special Car

- storage tank

- Machinery

- PPE

Wechat: +8615271357675

MOB: 86-152-71357675

ADD: NO.1 TAIZONG AVENUE GAOQIAO INDUSTRY PARK TAIWANESE INVESTMENT AREA DONGXIHU DISTRICT WUHAN CITY, HUBEI PROVINCE, P.R CHINA

Customize AWD Beiben Offroad 6X6 ANFO Explosives Mixing and Charging Truck

Bulk Explosive ANFO Mix tank: 17.3 m3 17000kg

fuel tank: 1.14 m3 1000kg

Charge efficiency 200-450kg/min

Measurement error ≤ 2%

Price for refer only. Final Price Offer Discount.

| Availability: | |

|---|---|

| Quantity: | |

|

| |

-

BCLH-15G , ND5310

-

BEIBEN TRUCK

-

8705909990

-

Shanghai, China

-

300

-

T/T

-

1

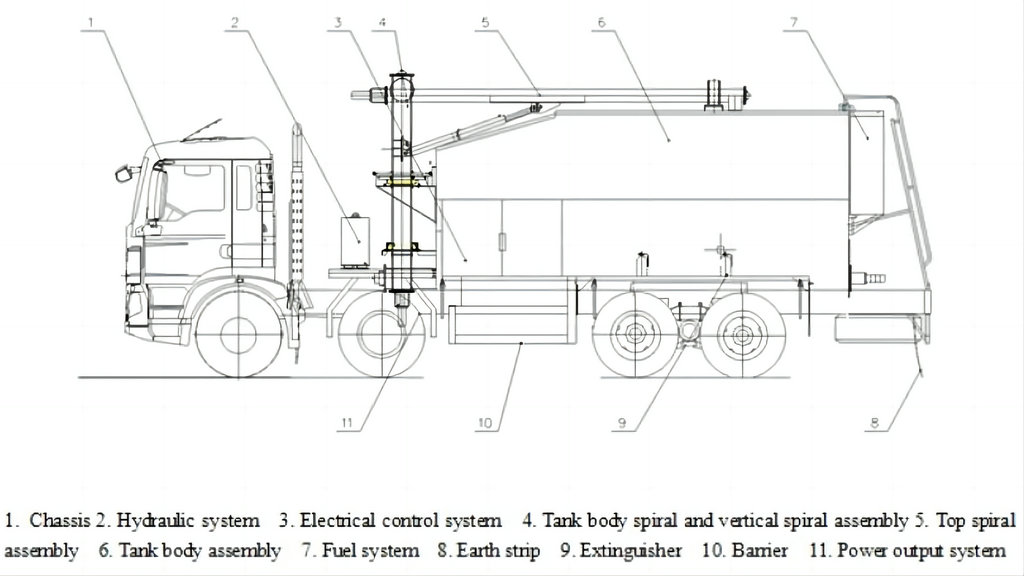

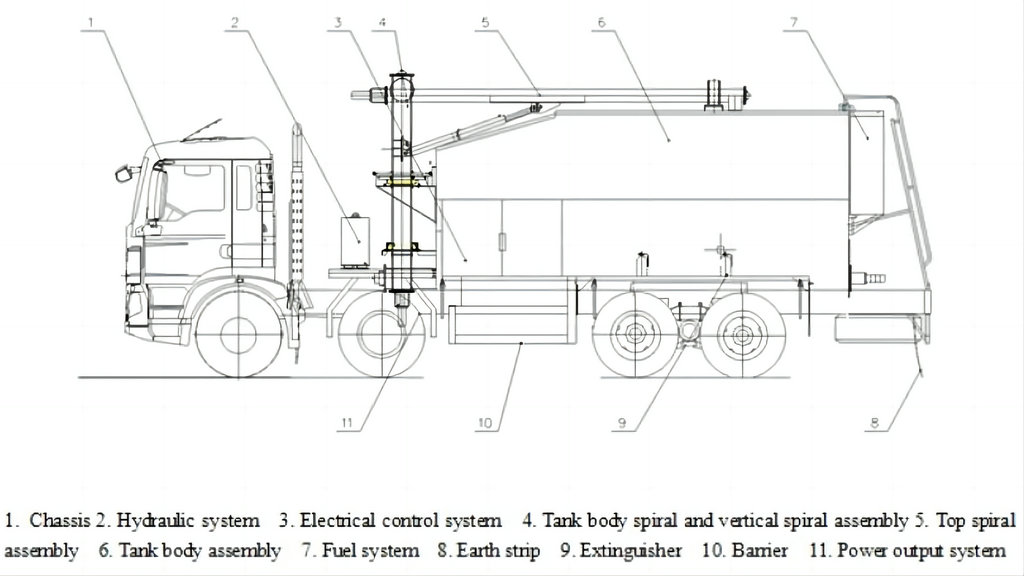

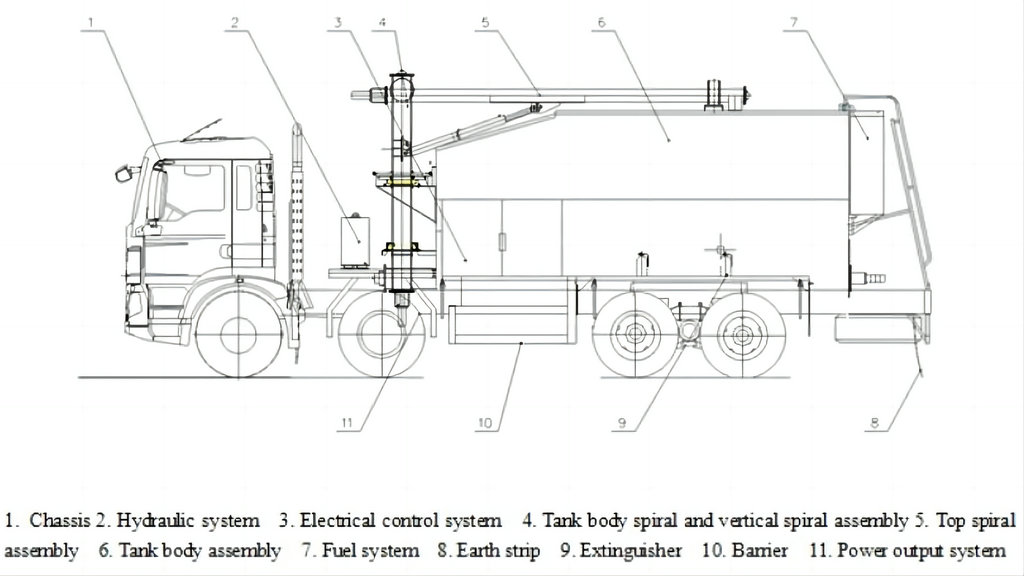

AWD Beiben Offroad 6X6 ANFO Explosives Mixing and Charging Truck

BCLH-15G Top discharge ANFO auger

BCLH-15G intelligent on-site mixed loading overhead ammonium explosives truck is used to mix porous granular ammonium explosives on site. It is mainly used for loading explosives in dry holes in open-pit mines. It adopts box screw, main, top and vertical screw delivery system, The charging efficiency is high, it can realize all-round charging, full computer operation control,with the function of stopping the material, and the work is safe and reliable.

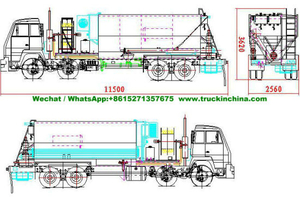

Effective volume of dry tank: 17.3 m3 Loading capacity: 17000kg

Effective volume of fuel tank: 1.14 m3 Loading capacity: 1000kg

Charge efficiency 200-450kg/min

Measurement error ≤ 2%

Total mass 32000kg

Overall dimensions length/width/height (10490 × 2460 × 3792mm)

15ton Heavy ANFO / Emulsion Explosives Mixing & Charging Truck

Main Features

Explosive raw material: granulated ammonium nitrate and diesel can be adjusted separately,

and make two materials reach best proportion, and the explosive can give full play to its energy.

Save labour density and cost.

Charging efficiency is high, blasting cost is low.

All the material will be loaded into the material tanks on the truck through grounding loading device, when reach the working site, mix and charge, real explosive can be formed, very safe and reliable.

The unfinished material can be returned, it is a high-technology product which integrated material transportation,

explosive mixing&making, hole charging etc. It can be named as mobile mini high-efficient explosive factory.

1 Application condition

1.1 Suitable for no-water hole charging, hole diameter ≥100mm

1.2 Suitable for open pit field touch working condition, can operate in hot summer cold winter,

sand-wind weather, low temperature etc. Working temperature range is -45ºC---+45ºC.

1.3 Can work normally under air relative humidity with 10%~90%.

1.4 Can work at the elevation of 2640m-5000m.

1.5 After years of application experience, SINOTRUCK chassis can fit for various mine tough road,

with excellent shock-absorption performance.

1.6 Braking system: Travelling brake(foot brake), auxiliary braking(Engine exhaust brake), emergency brake

(hand brake),good performance, when fully loaded, can reach the driving requirements of complex pavement.

2 Technical specification

2 Technical specification

2.1 Model:BCLH-15 on-site ANFO mixing&charging truck

2.2 Chassis: SINOTRUCK OR BEIBEN -NORTH BENZ 、SHACMAN available

Drive mode: 6*6

2.3 Mass and size

2.3.1 Mass

Self mass:15000kg

Max. Total mass:31000kg

2.3.2 Size:

Overall dimension:10190*2500*4000

Wheel base:front wheel:2022mm rear wheel:1830mm

Min. Ground clearance:314mm

2.4 Main performance

Rated loading capacity:15000kg

Charging efficiency:150-220kg/min

Rotation angle:360°

Deviation:±2%

Max. gradebility:35.1%

Min. Turning radius:10.85m

Max. Travelling speed:75km/h

2.5 Engine

Mode:In-line 6 cylinder, water cool charged, inter-cooling common rail diesel

engine

Model/Manufacturer:MC07.34- /SINOTRUCK(IV)

Emission standard:GB17691-2005 EURO3 、5、6

Rated power/rotation:248kw/( 2300r/min)

Max. Torque/rotation:1250Nm/(1200-1800 r/min)

Displacement: 6.87L

Idle speed: 600r/min

Note:If work in high altitude desert area, will equipped with desert filter core, to work under special

working condition.

2.6 Gearbox

Model/Manufacturer:HW13710C/SINOTRUCK with Neutral Switch

Mode:mechanical

Control mode:Mechanical manual

Forward gear ratio:10.52,7.83,5.85,4.35,3.25,2.42,1.8,1.34,1.00,0.75

Backward gear ratio:9.47,2.18

2.7 Differential mechanism

SINOTRUCK chassis has inter-wheel differential and interaxle differential, all with differential lock.

Inter-wheel differential lock is used to lock 1st and 2nd rear axle's inter-wheel differential.

The inter-wheel differential lock will be used only the truck is in straight driving status.

Interaxle differential is used to lock 1st and 2nd rear axle's interaxle differential.

2.8 Suspension system

2.8.1 mode:front suspension is parabola multi-leaf spring absorber with tube and stabilizer bar. Rear suspension is balance axle suspension system.

2.8.2 Axle:1st and 2nd axle is forged I-beam, axle load 6.5t, 3rd and 4th axle load is 13t, similar with BENZ driving axle, adopted central spiral bevel

gear and wheel rim cylindrical planetary gear double reduction, thus improve the truck's ground

clearance and its flexibility.

2.9 Tyre

Tyre size:12.00R~20

2.10 Braking system:

2.10.1 Mode:pedal control,double-circuit air pressure brake is the main braking system, engine exhaust brake is auxiliary braking system.

Spring energy storage and air brakecis the parking braking system.

2.11 Smoke vent:

Smoke vent outlet will be equipped with fire shield, and provide guarantee for explosive mixing.

2.12 Cabin:

All steel flat-roof cabin can roll over 70°,arc shape windshield glass, wide cabin, good view, equipped with

air-con, roof light, 3-arm&double speed glass wiper, fog-proof heater, radio etc.

The cabin has good sound insulation, noise standard is lower than national standard.

The cabin has standard double seat, open from both sides.

The cabin seat type is hydraulic suspension, can adjust up&down and forward&backward,

can suit for different drivers and reduce the fatigue.

The cabin is equipped with various display instrument, alarm, lighting, control switch, CD etc.

Steering wheel can be tilted. Equipped with electrical glass wiper and cleaner, stained safety glass,

window glass lifter, heater and defroster and air-con etc.

Steering gear is hydraulic powered mode

| Seq. | Name | Model | Specification | Manufacturer | Origin | Note |

| 1 | ANFO mixing&charging truck | BCLH-15G | ANFO mixing & charging truck | CHINA | CHINA | |

| 2 | Charging capacity | 15000kg | ||||

| 3 | Charging efficiency | 150-220kg/min | ||||

| 4 | Deviation | ±2% | ||||

| 5 | Chassis | 6x4 / 6*6/ 8x4 | Total mass 31000kg | SINOTRUCK /BEIBEN /SHACMAN | CHINA | |

| 6 | Engine | MC07.340 WP10.340 | Power 249kw | SINOTRUCK WEICHAI | GB IV | |

| 7 | Gearbox | HW13710C 9JS119 | SINOTRUCK /BEIBEN /SHACMAN | CHINA | ||

| 8 | Rear axle | 457 Benz MAN | Ratio 6.833 | SINOTRUCK /BEIBEN /SHACMAN | CHINA | |

| 9 | Braking system | Travelling brake, auxiliary brake and parking brake | SINOTRUCK /BEIBEN /SHACMAN | CHINA | ||

| 10 | Hydraulic motor | PVHW-45 | Pressure compensation variable pump | VICKERS | USA | |

| 11 | Hydraulic motor | 104-1068 104-1065 104-1063 | Low speed, big torque | EATON | USA | |

| 12 | Integrated valve block | For motor steering, rotation speed control | YUKEN | CHINA | ||

| 13 | ANFO mixing&making system | BCLH-15.7.2 Straight spiral assy. | Efficiency 150-220kg/min | CHINA | CHINA | |

| 14 | ANFO mixing&making system | BCLH-15.7.3 Top spiral assy. | Efficiency 150-220kg/min | CHINA | CHINA | |

| 15 | Flow meter | DN25 | Double indication system, teleportation signal, material shortage alarm and stop function | CHINA/JAPAN | JAPAN | |

| 16 | Control panel | Main board: FXIN-40MR | Data processment | MITSUBISHI | JANPAN | |

| 17 | Control panel | Touch screen: F930GOT-BWD-C | PLC touch screen show | MITSUBISHI | JANPAN |

BCLH-15G intelligent on-site mixed loading overhead ammonium explosives truck is used to mix porous granular ammoniumexplosives on site.It is mainly used for loading explosives in dryholes in open-pit mines.It adopts box screw,main,top andvertical screw delivery system,The charging efficiency is high,itcan realize all-round charging,full computer operation control,with the function of stopping the material,and the work is safeand reliable.

●Hydraulic pumps : PVG-100-F1UV-RGFY-P-1NN/FNN Auguire USA

● Hydraulic motors : Box Screw 1068 Straight Screw 1065 Top Screw 1063 Eaton USA

● Diesel oil pump : DM25 and DM4 Eaton USA

● Hydraulic valve : BCLH-15 Japan Oil Research Institute China

● Pressure sensor and flow sensor: Main part of the electrical system (contactor, PLC, LCD screen, ...)

Pressure Sensor BCLH-15 Shanghai Hydraulic Sensor Factory China

Flow sensor TFA/R1/M5/d/k2/L-20 Shanxi Honghe China

PLC: Mitsubishi Japan

Contactor DM8 Mitsubishi Japan

LCD screen 12 inch Mitsubishi Japan

ANFO Explosive Loading Trucks

BCLH-15G Top discharge ANFO auger

Main parts :Silo, screw conveying system, screw mixing system, hydraulic system and electrical control system. The operation is controlled by the electrical system, and various raw materials are mixed in a certain proportion and filled into the borehole, and the mixture reacts with each other to form ANFO. Optional oil pump.

| Seq. | Name | Model | Specification | Manufacturer | Origin | Note |

| 1 | ANFO mixing&charging truck | BCLH-15G | ANFO mixing&charging truck | CHINA | CHINA | |

| 2 | Charging capacity | 15000kg | ||||

| 3 | Charging efficiency | 150-220kg/min | ||||

| 4 | Deviation | ±2% | ||||

| 5 | Chassis | 6*6 | Total mass 31000kg | SINOTRUCK | CHINA | |

| 6 | Engine | MC07.34-40 | Power 249kw | SINOTRUCK | GB IV | |

| 7 | Gearbox | HW13710C | SINOTRUCK | CHINA | ||

| 8 | Rear axle | 457 Double bridge | Ratio 6.833 | SINOTRUCK | CHINA | |

| 9 | Braking system | Travelling brake, auxiliary brake and parking brake | SINOTRUCK | CHINA | ||

| 10 | Hydraulic motor | PVHW-45 | Pressure compensation variable pump | VICKERS | USA | |

| 11 | Hydraulic motor | 104-1068 104-1065 104-1063 | Low speed, big torque | EATON | USA | |

| 12 | Integrated valve block | For motor steering, rotation speed control | YUKEN | CHINA | ||

| 13 | ANFO mixing&making system | BCLH-15.7.2 Straight spiral assy. | Efficiency 150-350kg/min | CHINA | CHINA | |

| 14 | ANFO mixing&making system | BCLH-15.7.3 Top spiral assy. | Efficiency 150-350kg/min | CHINA | CHINA | |

| 15 | Flow meter | DN25 | Double indication system, teleportation signal, material shortage alarm and stop function | CHINA/JAPAN | JAPAN | |

| 16 | Control panel | Main board: FXIN-40MR | Data processment | MITSUBISHI | JANPAN | |

| 17 | Control panel | Touch screen: F930GOT-BWD-C | PLC touch screen show | MITSUBISHI | JANPAN |

The components of ANFO are usually mixed close to the point of operation for safety reasons. The final product, once mixed, is relatively safe and easy to handle. It is used by augering it into drill holes.

Ammonium Nitrate/Fuel Oil

is widely used in

coal mining,

quarrying, metal

mining, and civil construction. It’s best used in undemanding applications where its low cost and relative ease of use makes it a cost effective solution. It is estimated that ANFO accounts for an estimated 80% of explosives used annually around the world. To keep costs as low as possible, bulk ANFO is used, i.e. it is mixed on-site, near the borehole by a bulk truck

Emulsion explosives type BCRH-15;

Granulated explosives of ANFO type BCLH-15;

Mixed Heavy ANFO explosives BCZH-15.

The main container of the truck has two multifunctional tanks, which allow transporting emulsion UN 3375 or ammonium nitrate UN 1942.

when the truck is loaded only with components of the emulsion explosive (manufacturing and charging boreholes only with emulsion explosive) the truck’s capacity is 10~22 tons;

when the truck is loaded only with components of ANFO (manufacturing and charging boreholes only with ANFO) the truck’s capacity is 14,5 tons;

when the truck is loaded only with components of mixed explosives (30% ANFO + 70% emulsion explosives) the truck’s capacity is 16 tons;

The truck has the ability to charge the industrial explosives of varying density that allows you to charge units with different spacing.

Technological equipment of the truck enables the production of explosives on the basis of various emulsions both hot and cold type. For this purpose, the truck has two tanks for gassing agent of two different formulations.

Truck equipment is mounted on Sinotruck HOWO 8x4 chassis with MAN Tech MC Engine , which provides the truck with improved driving characteristics on the charging unit (reducing the likelihood of boreholes filling up, receiving better handling, and the geometric flotation).

Emulsion mixing and charging truck BEIBEN 8x4 Euro 3/5/6 Chassis : ND13101D41J

Overall dimensions: | 11600×2500×3840(mm) | Fuel Type: | Diesel oil |

GW | 31000(Kg) | ||

NW | 18500(Kg) | Rated load mass: | The 12370123-05 (Kg) |

Approach Angle/Departure Angle: | 27/10 (°) | Front/rear overhang: | 1410/3090(mm) |

Axle Load: | 6500/6500/18000(with double axle) | Wheelbase: | 1500+4150+1450(mm) |

Number of shafts: | 4 | Maximum speed: | 80(km/h) |

Number of tires: | 12(PCS) | Tire Specifications: | 315/80R22.5 16PR,12R22.5 18PR |

Fuel consumption: | (40.2 L / 100 km) | Number of spring pieces: | 12/12/13 |

Front wheel base: | 1995/1995(mm) | Rear wheel base: | 1800/1800(mm) |

Engine type | Engine manufacturer | Volume (ml) | Power (kw) |

WP10.336 | Weichai Power Co., Ltd. | 9726 | 247 |

Optional transport medium: non-explosive emulsion composed of ammonium nitrate solution, oil and emulsifier The vehicle drives to the job site, starts the PTO, extends the drug delivery hose into the bottom of the hole, starts to inject raw materials, slowly lifts the drug delivery hose, and the raw materials are loaded in the drill hole. | |||

Refer News : 2 Sets HOWO Offroad AWD 6x6 Mixing And Charging ANFO Explosive Trucks Delivery

Refer News : 2 Sets HOWO Offroad AWD 6x6 Mixing And Charging ANFO Explosive Trucks Delivery

AWD Beiben Offroad 6X6 ANFO Explosives Mixing and Charging Truck

BCLH-15G Top discharge ANFO auger

BCLH-15G intelligent on-site mixed loading overhead ammonium explosives truck is used to mix porous granular ammonium explosives on site. It is mainly used for loading explosives in dry holes in open-pit mines. It adopts box screw, main, top and vertical screw delivery system, The charging efficiency is high, it can realize all-round charging, full computer operation control,with the function of stopping the material, and the work is safe and reliable.

Effective volume of dry tank: 17.3 m3 Loading capacity: 17000kg

Effective volume of fuel tank: 1.14 m3 Loading capacity: 1000kg

Charge efficiency 200-450kg/min

Measurement error ≤ 2%

Total mass 32000kg

Overall dimensions length/width/height (10490 × 2460 × 3792mm)

15ton Heavy ANFO / Emulsion Explosives Mixing & Charging Truck

Main Features

Explosive raw material: granulated ammonium nitrate and diesel can be adjusted separately,

and make two materials reach best proportion, and the explosive can give full play to its energy.

Save labour density and cost.

Charging efficiency is high, blasting cost is low.

All the material will be loaded into the material tanks on the truck through grounding loading device, when reach the working site, mix and charge, real explosive can be formed, very safe and reliable.

The unfinished material can be returned, it is a high-technology product which integrated material transportation,

explosive mixing&making, hole charging etc. It can be named as mobile mini high-efficient explosive factory.

1 Application condition

1.1 Suitable for no-water hole charging, hole diameter ≥100mm

1.2 Suitable for open pit field touch working condition, can operate in hot summer cold winter,

sand-wind weather, low temperature etc. Working temperature range is -45ºC---+45ºC.

1.3 Can work normally under air relative humidity with 10%~90%.

1.4 Can work at the elevation of 2640m-5000m.

1.5 After years of application experience, SINOTRUCK chassis can fit for various mine tough road,

with excellent shock-absorption performance.

1.6 Braking system: Travelling brake(foot brake), auxiliary braking(Engine exhaust brake), emergency brake

(hand brake),good performance, when fully loaded, can reach the driving requirements of complex pavement.

2 Technical specification

2 Technical specification

2.1 Model:BCLH-15 on-site ANFO mixing&charging truck

2.2 Chassis: SINOTRUCK OR BEIBEN -NORTH BENZ 、SHACMAN available

Drive mode: 6*6

2.3 Mass and size

2.3.1 Mass

Self mass:15000kg

Max. Total mass:31000kg

2.3.2 Size:

Overall dimension:10190*2500*4000

Wheel base:front wheel:2022mm rear wheel:1830mm

Min. Ground clearance:314mm

2.4 Main performance

Rated loading capacity:15000kg

Charging efficiency:150-220kg/min

Rotation angle:360°

Deviation:±2%

Max. gradebility:35.1%

Min. Turning radius:10.85m

Max. Travelling speed:75km/h

2.5 Engine

Mode:In-line 6 cylinder, water cool charged, inter-cooling common rail diesel

engine

Model/Manufacturer:MC07.34- /SINOTRUCK(IV)

Emission standard:GB17691-2005 EURO3 、5、6

Rated power/rotation:248kw/( 2300r/min)

Max. Torque/rotation:1250Nm/(1200-1800 r/min)

Displacement: 6.87L

Idle speed: 600r/min

Note:If work in high altitude desert area, will equipped with desert filter core, to work under special

working condition.

2.6 Gearbox

Model/Manufacturer:HW13710C/SINOTRUCK with Neutral Switch

Mode:mechanical

Control mode:Mechanical manual

Forward gear ratio:10.52,7.83,5.85,4.35,3.25,2.42,1.8,1.34,1.00,0.75

Backward gear ratio:9.47,2.18

2.7 Differential mechanism

SINOTRUCK chassis has inter-wheel differential and interaxle differential, all with differential lock.

Inter-wheel differential lock is used to lock 1st and 2nd rear axle's inter-wheel differential.

The inter-wheel differential lock will be used only the truck is in straight driving status.

Interaxle differential is used to lock 1st and 2nd rear axle's interaxle differential.

2.8 Suspension system

2.8.1 mode:front suspension is parabola multi-leaf spring absorber with tube and stabilizer bar. Rear suspension is balance axle suspension system.

2.8.2 Axle:1st and 2nd axle is forged I-beam, axle load 6.5t, 3rd and 4th axle load is 13t, similar with BENZ driving axle, adopted central spiral bevel

gear and wheel rim cylindrical planetary gear double reduction, thus improve the truck's ground

clearance and its flexibility.

2.9 Tyre

Tyre size:12.00R~20

2.10 Braking system:

2.10.1 Mode:pedal control,double-circuit air pressure brake is the main braking system, engine exhaust brake is auxiliary braking system.

Spring energy storage and air brakecis the parking braking system.

2.11 Smoke vent:

Smoke vent outlet will be equipped with fire shield, and provide guarantee for explosive mixing.

2.12 Cabin:

All steel flat-roof cabin can roll over 70°,arc shape windshield glass, wide cabin, good view, equipped with

air-con, roof light, 3-arm&double speed glass wiper, fog-proof heater, radio etc.

The cabin has good sound insulation, noise standard is lower than national standard.

The cabin has standard double seat, open from both sides.

The cabin seat type is hydraulic suspension, can adjust up&down and forward&backward,

can suit for different drivers and reduce the fatigue.

The cabin is equipped with various display instrument, alarm, lighting, control switch, CD etc.

Steering wheel can be tilted. Equipped with electrical glass wiper and cleaner, stained safety glass,

window glass lifter, heater and defroster and air-con etc.

Steering gear is hydraulic powered mode

| Seq. | Name | Model | Specification | Manufacturer | Origin | Note |

| 1 | ANFO mixing&charging truck | BCLH-15G | ANFO mixing & charging truck | CHINA | CHINA | |

| 2 | Charging capacity | 15000kg | ||||

| 3 | Charging efficiency | 150-220kg/min | ||||

| 4 | Deviation | ±2% | ||||

| 5 | Chassis | 6x4 / 6*6/ 8x4 | Total mass 31000kg | SINOTRUCK /BEIBEN /SHACMAN | CHINA | |

| 6 | Engine | MC07.340 WP10.340 | Power 249kw | SINOTRUCK WEICHAI | GB IV | |

| 7 | Gearbox | HW13710C 9JS119 | SINOTRUCK /BEIBEN /SHACMAN | CHINA | ||

| 8 | Rear axle | 457 Benz MAN | Ratio 6.833 | SINOTRUCK /BEIBEN /SHACMAN | CHINA | |

| 9 | Braking system | Travelling brake, auxiliary brake and parking brake | SINOTRUCK /BEIBEN /SHACMAN | CHINA | ||

| 10 | Hydraulic motor | PVHW-45 | Pressure compensation variable pump | VICKERS | USA | |

| 11 | Hydraulic motor | 104-1068 104-1065 104-1063 | Low speed, big torque | EATON | USA | |

| 12 | Integrated valve block | For motor steering, rotation speed control | YUKEN | CHINA | ||

| 13 | ANFO mixing&making system | BCLH-15.7.2 Straight spiral assy. | Efficiency 150-220kg/min | CHINA | CHINA | |

| 14 | ANFO mixing&making system | BCLH-15.7.3 Top spiral assy. | Efficiency 150-220kg/min | CHINA | CHINA | |

| 15 | Flow meter | DN25 | Double indication system, teleportation signal, material shortage alarm and stop function | CHINA/JAPAN | JAPAN | |

| 16 | Control panel | Main board: FXIN-40MR | Data processment | MITSUBISHI | JANPAN | |

| 17 | Control panel | Touch screen: F930GOT-BWD-C | PLC touch screen show | MITSUBISHI | JANPAN |

BCLH-15G intelligent on-site mixed loading overhead ammonium explosives truck is used to mix porous granular ammoniumexplosives on site.It is mainly used for loading explosives in dryholes in open-pit mines.It adopts box screw,main,top andvertical screw delivery system,The charging efficiency is high,itcan realize all-round charging,full computer operation control,with the function of stopping the material,and the work is safeand reliable.

●Hydraulic pumps : PVG-100-F1UV-RGFY-P-1NN/FNN Auguire USA

● Hydraulic motors : Box Screw 1068 Straight Screw 1065 Top Screw 1063 Eaton USA

● Diesel oil pump : DM25 and DM4 Eaton USA

● Hydraulic valve : BCLH-15 Japan Oil Research Institute China

● Pressure sensor and flow sensor: Main part of the electrical system (contactor, PLC, LCD screen, ...)

Pressure Sensor BCLH-15 Shanghai Hydraulic Sensor Factory China

Flow sensor TFA/R1/M5/d/k2/L-20 Shanxi Honghe China

PLC: Mitsubishi Japan

Contactor DM8 Mitsubishi Japan

LCD screen 12 inch Mitsubishi Japan

ANFO Explosive Loading Trucks

BCLH-15G Top discharge ANFO auger

Main parts :Silo, screw conveying system, screw mixing system, hydraulic system and electrical control system. The operation is controlled by the electrical system, and various raw materials are mixed in a certain proportion and filled into the borehole, and the mixture reacts with each other to form ANFO. Optional oil pump.

| Seq. | Name | Model | Specification | Manufacturer | Origin | Note |

| 1 | ANFO mixing&charging truck | BCLH-15G | ANFO mixing&charging truck | CHINA | CHINA | |

| 2 | Charging capacity | 15000kg | ||||

| 3 | Charging efficiency | 150-220kg/min | ||||

| 4 | Deviation | ±2% | ||||

| 5 | Chassis | 6*6 | Total mass 31000kg | SINOTRUCK | CHINA | |

| 6 | Engine | MC07.34-40 | Power 249kw | SINOTRUCK | GB IV | |

| 7 | Gearbox | HW13710C | SINOTRUCK | CHINA | ||

| 8 | Rear axle | 457 Double bridge | Ratio 6.833 | SINOTRUCK | CHINA | |

| 9 | Braking system | Travelling brake, auxiliary brake and parking brake | SINOTRUCK | CHINA | ||

| 10 | Hydraulic motor | PVHW-45 | Pressure compensation variable pump | VICKERS | USA | |

| 11 | Hydraulic motor | 104-1068 104-1065 104-1063 | Low speed, big torque | EATON | USA | |

| 12 | Integrated valve block | For motor steering, rotation speed control | YUKEN | CHINA | ||

| 13 | ANFO mixing&making system | BCLH-15.7.2 Straight spiral assy. | Efficiency 150-350kg/min | CHINA | CHINA | |

| 14 | ANFO mixing&making system | BCLH-15.7.3 Top spiral assy. | Efficiency 150-350kg/min | CHINA | CHINA | |

| 15 | Flow meter | DN25 | Double indication system, teleportation signal, material shortage alarm and stop function | CHINA/JAPAN | JAPAN | |

| 16 | Control panel | Main board: FXIN-40MR | Data processment | MITSUBISHI | JANPAN | |

| 17 | Control panel | Touch screen: F930GOT-BWD-C | PLC touch screen show | MITSUBISHI | JANPAN |

The components of ANFO are usually mixed close to the point of operation for safety reasons. The final product, once mixed, is relatively safe and easy to handle. It is used by augering it into drill holes.

Ammonium Nitrate/Fuel Oil

is widely used in

coal mining,

quarrying, metal

mining, and civil construction. It’s best used in undemanding applications where its low cost and relative ease of use makes it a cost effective solution. It is estimated that ANFO accounts for an estimated 80% of explosives used annually around the world. To keep costs as low as possible, bulk ANFO is used, i.e. it is mixed on-site, near the borehole by a bulk truck

Emulsion explosives type BCRH-15;

Granulated explosives of ANFO type BCLH-15;

Mixed Heavy ANFO explosives BCZH-15.

The main container of the truck has two multifunctional tanks, which allow transporting emulsion UN 3375 or ammonium nitrate UN 1942.

when the truck is loaded only with components of the emulsion explosive (manufacturing and charging boreholes only with emulsion explosive) the truck’s capacity is 10~22 tons;

when the truck is loaded only with components of ANFO (manufacturing and charging boreholes only with ANFO) the truck’s capacity is 14,5 tons;

when the truck is loaded only with components of mixed explosives (30% ANFO + 70% emulsion explosives) the truck’s capacity is 16 tons;

The truck has the ability to charge the industrial explosives of varying density that allows you to charge units with different spacing.

Technological equipment of the truck enables the production of explosives on the basis of various emulsions both hot and cold type. For this purpose, the truck has two tanks for gassing agent of two different formulations.

Truck equipment is mounted on Sinotruck HOWO 8x4 chassis with MAN Tech MC Engine , which provides the truck with improved driving characteristics on the charging unit (reducing the likelihood of boreholes filling up, receiving better handling, and the geometric flotation).

Emulsion mixing and charging truck BEIBEN 8x4 Euro 3/5/6 Chassis : ND13101D41J

Overall dimensions: | 11600×2500×3840(mm) | Fuel Type: | Diesel oil |

GW | 31000(Kg) | ||

NW | 18500(Kg) | Rated load mass: | The 12370123-05 (Kg) |

Approach Angle/Departure Angle: | 27/10 (°) | Front/rear overhang: | 1410/3090(mm) |

Axle Load: | 6500/6500/18000(with double axle) | Wheelbase: | 1500+4150+1450(mm) |

Number of shafts: | 4 | Maximum speed: | 80(km/h) |

Number of tires: | 12(PCS) | Tire Specifications: | 315/80R22.5 16PR,12R22.5 18PR |

Fuel consumption: | (40.2 L / 100 km) | Number of spring pieces: | 12/12/13 |

Front wheel base: | 1995/1995(mm) | Rear wheel base: | 1800/1800(mm) |

Engine type | Engine manufacturer | Volume (ml) | Power (kw) |

WP10.336 | Weichai Power Co., Ltd. | 9726 | 247 |

Optional transport medium: non-explosive emulsion composed of ammonium nitrate solution, oil and emulsifier The vehicle drives to the job site, starts the PTO, extends the drug delivery hose into the bottom of the hole, starts to inject raw materials, slowly lifts the drug delivery hose, and the raw materials are loaded in the drill hole. | |||

Refer News : 2 Sets HOWO Offroad AWD 6x6 Mixing And Charging ANFO Explosive Trucks Delivery

Refer News : 2 Sets HOWO Offroad AWD 6x6 Mixing And Charging ANFO Explosive Trucks Delivery

Related Products

SUCCESS CASES

More >>- 2026-02-013PCS T7 PE Lined ISO Tank Container for Potassium Hydroxide KOH, HCL Hydrochloric Acid, Hydrogen Peroxide for India

3PCS T7 PE Lined ISO Tank Container for Potassium Hydroxide KOH, HCL Hydrochloric Acid, Hydrogen Peroxide for India DTAU2601014 DTAU2601020 DTAU2601035 Vessel/Voyage:SHUN GANG CHANG JIE V.L2602E B/L Date: FEB. 01,2026 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2026-01-16T14 T7 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) , Potassium Hydroxide KOH, HCL Hydrochloric Acid, for India

T14 T7 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India DTAU2512010 DTAU2512025 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2025-12-1212KL Polyethylene PE Lined Tank Body for Hydrochloric Acid HCL Cargo Truck To Vietnam

12KL Polyethylene PE Lined Tank Body for Hydrochloric Acid HCL Cargo Truck To Vietnam

- 2025-11-11T7 T14 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India

T7 T14 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India DHF, HCL,KOH , H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide 20FT TANK CONTAINER (EMPTY AND NEW TANKS) DTAU2509090 DTAU2509103 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2025-09-28Advantages And Disadvantages of Different Material Storage T8 T14 PE / PTFE Lined ISO Tank Container for Electronic Grade Hydrogen Peroxide (H₂O₂) HCL,KOH

Advantages And Disadvantages of Different Material Storage T8 T14 PE / PTFE Lined ISO Tank Container for Electronic Grade Hydrogen Peroxide (H₂O₂) DTAU2509016 DTAU2509021 DTAU2509037

- 2025-09-016PCS T7 T14 PE Lined ISO Tank Container for HCL, PAC Hydrochloric Acid / Chemical Poly Aluminum Chloride 21KL To Vietnam

6PCS T7 T14 PE Lined ISO Tank Container for HCL, PAC Hydrochloric Acid / Chemical Poly Aluminum Chloride 21KL To Vietnam road transport type PE Lined Tank Used to contain: HCl , NaOH , PAC , H2SO4(max 98%) etc. Tank Capacity: 21,000 Liters 21m3 Steel sheet 6mm, head 6mm Liner thickness: 16mm PE 20 FT TANK (EMPTY AND NEW TANKS) HCDA2505016 HCDA2505021 HCDA2505037 HCDA2505042 HCDA2505058 HCDA2505063

- 2025-08-293 Units PE Lined T7 T8 T14 ISO Tank Container for DHF,HCL,KOH,H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide Export To India

3 Units PE Lined T7 T8 T14 ISO Tank Container for DHF,HCL,KOH,H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide Export To India DTAU2508010 DTAU2508025 DTAU2508030 20FT TANK CONTAINER (EMPTY AND NEW TANKS)

- 2025-06-1820PCS UN 3394 3399 Portable Tanks C-480 TMA Cylinders to USA

20PCS UN 3394 3399 Portable Tanks C-480 TMA Cylinders to USA PORTABLE TANK (EMPTY AND NEW TANKS) C-480 CYLINDER HS:860900.00(USA) Adr/Rid Organometallic Substance, Liquid, Water- Reactive C-480 Saddle Type Portable Tank, tank capacity 1880L KS1880-T21 Portable Tanks ASME Test DATA Report(C250051-C250070) BV Certificate No.:IIC-BVCT2570036S KSVU 250051 -70 Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg

- 2025-04-034 Units T14 ISO Tank Container PE Lined for Hydrofluoric HF Hydrochloric Acid HCL, Ferric Chloride Potassium Hydroxide KOH Tank Container Export To India

4 Units T14 ISO Tank Container PE Lined for Hydrofluoric HF Hydrochloric Acid HCL, Ferric Chloride Potassium Hydroxide KOH Tank Container Export To India DTAU2502011 DTAU2502027 DTAU2502032 DTAU2502048 20 FT TANK CONTAINER FOR HYDROCHLORIC ACID UN1789 HCL, HYDROFLUORIC ACID UN1790 HF ACID CARON STEEL AND LINED WITH 16MM LLDPE TANKS CAPACITY 21 KL FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, TOP UNLOADING TARE WEIGHT 5200KG 1UNIT 20FT TANK CONTAINER FOR UN1814 KOH POTASSIUM HYDROXIDE 45% SOLUTION DISH HEAD TYPE TANK CAPACITY: 19000LITERS FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, BOTTOM UNLOADING TARE WEIGHT 5300KG 1UNIT 20FT TANK CONTAINER FOR UN2014 H2O2 HYDROGEN PEROXIDE 31% SOLUTION DISH HEAD TYPE TANK CAPACITY: 19000LITERS FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, BOTTOM UNLOADING TARE WEIGHT 5300KG 2UNITS

- 2025-04-01Steel Lined PE Plastic ISO Tank for Hydrochloric Acid HCL12KL,15KL/16KL/19KL/22KL To Vietnam

Steel Lined PE Plastic ISO Tank for Hydrochloric Acid HCL12KL,15KL/16KL/19KL/22KL To Vietnam Description of goods Quantity N.W PE LINED STEEL TANK 5100X 2350 X 1400MM / 12.5M3 (EMPTY AND NEW TANKS) MODEL: DTA5212 HS CODE : 7309000000 、6300KGS PE LINED STEEL TANK 6040 X 2400 X 1600MM / 15.8M3 (EMPTY AND NEW TANKS) MODEL: DTA5215 HS CODE : 7309000000 1 3650KG PE LINED STEEL TANK 7190 X 2300X 1300MM / 16.2M3 (EMPTY AND NEW TANKS) MODEL: DTA5316 HS CODE : 7309000000 、4350KG PE LINED STEEL TANK 8520 X 2260 X 1350MM / 19.5M3 (EMPTY AND NEW TANKS) MODEL: DTA5319 HS CODE : 7309000000 、4850KG 20 FT TANK CONTAINER 6058X2438X2591MM / 22.8M3 (EMPTY AND NEW TANKS) MODEL: DTAU2501015 、5800KG

- 2025-02-261000L SS304 Stainless Steel Lined PE Plastic Tank for Hydrochloric Acid to GUAYAQUIL, EC

1000L SS304 Stainless Steel Lined PE Plastic Tank for Hydrochloric Acid to GUAYAQUIL, EC STORAGE TANK 304 STAINLESS STEEL LINED PLASTIC TANK VERTICAL TANK STAINLESS STEEL 304 THICKNESS 5MM+PE 16MM CAPACITY: 1,000 L RESIST 15%~38% HYDROCHLORIC ACID HS CODE:730900

- 2025-01-1920PCS Metal Alky TEAL C480 T21 UN Portable Tank Cylinders To USA

20Units UN T21 Portable Tank Container 1880L Cylinder For TEAL Metal Alkyls UN3394 UN3399 to USA with 30pcs Spare PSV RELIEF VALVES SF/A412F-25P(3B) Manufacturer (SHENYANG XINGUANG VALVE ) KS1880-T21 Portable Tanks Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg KSVU240016 -KSVU240035 Adr/Rid Organometallic Substance, Liquid, Water- Reactive C-480 Saddle Type Portable Tank, tank capacity 1880L

- 2024-12-206 Sets Thermal Insulated LLDPE Lined Tanks 25KL for Sodium Hypochlorite Hydrochloric Acid Storage Transport Tanker To Saudi Arabia

6 Sets Thermal Insulated LLDPE Lined Tanks 25KL for Sodium Hypochlorite Hydrochloric Acid To Saudi Arabia Lined PE Tanks 6604Gallon For Truck Trailer mounted FROM WUHAN PORT CHINA TO DAMMAM, SAUDI ARABIA BY SEA. + Port of loading : WUHAN PORT + Port of unloading :DAMMAM SAUDI ARABIA

- 2024-12-022 Units T14 Hydrofluoric Hydrochloric Acid UN1789 UN1790 ISOTank Container Road Transport For ASCOR

2 Units T14 Hydrofluoric Hydrochloric Acid UN1789 UN1790 ISOTank Container Road Transport For ASCOR 20FT Tank Container (EMPTY AND NEW TANKS) FOR HYDROCHLORIC ACID UN1789 HCL HYDROFLUORIC ACID HF ACID UN1790 CARBON STEEL AND LINED WITH 16MM LLDPE DTAU2404015, DTAU2404020

- 2024-10-245 Units C480 Keystone Vessel T21 TEAL Cylinder UN Portable Tanks To SAUDI ARABIA

5 Units Keystone Vessel T21 TEAL UN Portable Tank C480 Cylinder To SAUDI ARABIA KS1880-T21 Portable Tanks Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg KSVU2400114 KSVU2400120 KSVU2400135 KSVU2400140 KSVU2400156