Special Vehicles

- Aerial platform truck

- Dolly Trailer

- ISO Tank

- Recovery Trucks

- Road Sweeper

- SKD Truck Body

- Special Vehicle

- Tank Trailer

- Tank Truck

- Truck Accessories Parts

- All Wheel Drive off road truck

- Beiben truck Customizing

- Body parts

- Concrete mixer trucks

- Crane truck

- Environmental Trucks

- Fire Trucks

- ISUZU UD HINO Truck Customizing

- IVECO FOTON-FAW JAC Customizing

- Portable Tank Container

- Recovery Trucks Wrecker

- Road tanker

- SHACMAN Truck Customizing

- Special Car

- storage tank

- Machinery

- PPE

Wechat: +8615271357675

MOB: 86-152-71357675

ADD: NO.1 TAIZONG AVENUE GAOQIAO INDUSTRY PARK TAIWANESE INVESTMENT AREA DONGXIHU DISTRICT WUHAN CITY, HUBEI PROVINCE, P.R CHINA

ISUZU GIGA Water Purification Vehicle 1000L/H

Water Purification Vehicle Truck Mounted Purification System Equipment Vehicle

Price for refer only. Final Price Offer Discount.

| Availability: | |

|---|---|

| Quantity: | |

|

| |

-

5201XJS

-

ISUZU

-

87059099900

-

Shanghai, China

-

3000

-

T/T

ISUZU GIGA Water Purification Vehicle

Army Portable Water Treatment Units  Water Purification Vehicle Truck mounted Purification System Equipment Vehicle

Water Purification Vehicle Truck mounted Purification System Equipment Vehicle

ISUZU GIGA Chassis 6x4 QL1251FTFZY

Special Vehicle Overall Size 9480,11585,10165 x 2540 x 3800 (mm)

Chassis | Chassis Model | QL1251FTFZY |

Wheelbase | 4650+1350 mm 4650+1370,5700+1370,5100+1370mm | |

Gross Weight | 25000kgs | |

Curb Weight | 14500kgs | |

Engine | Engine Model | 6HK1-TCG60 ,221 KW/301HP |

Type | Multi cylinder, 4stroke, 6-cylinder water cooled, direct fuel injection, turbo-diesel engine. | |

Displacement Volume(ml) | 7790 | |

Net Power(KW) | Min 300 HP at rated RPM | |

Fuel Type | Diesel | |

Emission Standard | Eour 6 | |

Clutch System | Model | Single Plate, dry friction |

Steering System | Power Steering | Left hand driving, |

Transmission System | Manually Operated | RT-11509C |

Brake System | Service Brake | Hydraulic disk brakes |

Park Brake | Air Brake & Hand Brake | |

Suspension System(Front & Rear) | Semi-elliptical leaf spring with telessopic shock absorber (both front & rear) | |

Type | Type Quantity | 10 pcs |

Type Specification | 295/80R22.5 18PR | |

Cabin | The cabine of 3 person (including driver), cruise control, ABS, air conditgioning, electric glass, adjustable headlights, USB, etc. | |

unpurified water tank | Tank Capacity | 3 m³ |

Tank Material | SS304 Stainless steel | |

Purified Water tank | Tank Capacity | 1.5 m³ |

Tank Material | SS304 Stainless steel | |

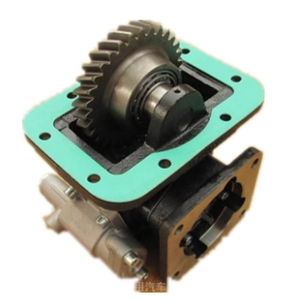

PTO | PTO power take-off take | |

Paint | Tank color is according to client’s requirements. | |

Thermal insulation of large board car: the total heat transfer coefficient of the car is less than 2.5 W/m2 · ℃

The wall panels of the large carriage are of sandwich structure

The inner and outer skins are 1.2mm aluminum plates, and the middle is rigid polyurethane foam sandwich layer and aluminum profile reinforced beam skin, aluminum alloy skeleton and polyurethane foam, which are bonded with special large plate adhesive, and then hot pressed once by the large plate press

Wall panel thickness 51.4mm

High temperature resistance of wall panels: can withstand high temperatures of 70 ℃ without degumming;

Low temperature resistance of wall panels: can withstand -55 ℃ low temperature without degumming;

Sunlight resistance of wall panel: under the condition of 1120w/m2 of radiant intensity, deformation, stickiness, cracking, damage, etc. will not occur;

Mold resistance of wall panels: able to withstand the harmful effects of various molds and fungi;

Humidity resistance of wall panels: able to withstand a relative humidity of no more than 95% (40 ℃);

Salt spray corrosion resistance of wall panels: able to resist the harmful effects of salt spray corrosion environment in coastal areas of China;

Wall panel flame retardancy: It has flame retardancy and can self extinguish when left on fire;

Environmental friendliness of wall panels: meeting E0 level environmental protection requirements

The large plate structure has good airtightness (water and air tightness), thermal insulation, sound insulation, waterproof, fireproof, heat radiation resistant, salt spray corrosion resistant, insect resistant, and other performance; By optimizing the reasonable layout of the skeleton and the design of the skeleton structure, the optimal values between the stiffness, strength, and weight of each board are achieved, which not only ensures the overall strength, stiffness, and weight requirements of the car body, but also achieves the goals of thermal insulation and sound insulation, fully reflecting the superiority of the large board car. When designing, full consideration should be given to the requirements for thermal insulation performance. Heat blocking should be installed at all skeleton positions inside the large panel to reduce heat loss in the carriage and improve the thermal insulation performance of the carriage

The carriage has sufficient strength and stiffness to withstand the vibrations and impacts of the car during operation. The structure of the large panel shelter complies with GJB6109-2007 "General Specification for Military Shelters"

The boards of the carriage are connected by riveting and high-strength bolts to form a whole, ensuring that the carriage has sufficient strength and stiffness to withstand the vibration and impact of the car during driving. The structure of the large board is shown in the following figure. All openings should be sealed; All cables and pipelines are sealed with insulation

Both the inner and outer skins are made of aluminum alloy, a thin sheet of aluminum, and anodized. The carriage wall panel has good sealing, heat insulation, and good strength and stiffness. The pressing of the carriage wall panel is controlled using our factory's typical process, and the structural design is carried out in accordance with GJB5113 "General Specification for Logistics Box Cars" to ensure that after various tests, the surface and structural components of the carriage are free from defects such as bending, warping, fracture, delamination, detachment, damage, damage, and permanent deformation.

Wall panel flatness: 1600mm × Within the range of 700mm, the flatness error shall not exceed 1.5mm,

Wall panel strength: can withstand uniformly distributed static load: ≥ 2kN/m2; Concentrated static load: area of 300mm × 600mm, static

Load ≥ 3kN.

Painting treatment of the interior surface of the car

The interior floor of the carriage is made of patterned aluminum plates

heater

Rated pressure: ≥ 0.7 MPa;

Wire section requirements: 6 square millimetre

Overall dimensions (length × wide × Height: ≤ 410x260x70 mm;

Net weight: ≤ 3.3 kilograms

Rated power: ≤ 8500W;

Rated voltage: 220V;

Operation mode: touch control;

Applicable number of people: ≥ 4 or more

Small generator

Rated power: ≥ 3KW

Backup power: ≥ 3 2KW

Rated frequency: 50HZ

Rated voltage: 380V

Structure type: open frame/hand push type

Power factor: 1.0

Number of phases: single-phase/three-phase

DC output: ≥ 12-8.3 (V-A)

Working time: ≥ 8H

Machine weight: ≤ 77kg

External dimensions: ≤ 660 * 550 * 600mm

Water purifier

Net water flow rate: ≥ 1000L/h (25 ℃);

Suitable water quality: surface water of three types;

Effluent quality: drinking water standard;

Overall dimensions (length × wide × Height: ≤ 1750mm × 800mm × 1700mm;

Weight: ≤ 750kg.

The system adopts a "pre-treatment+single stage reverse osmosis" water treatment process, with a reasonable design, stable operation, and water production quality that meets the requirements.

The equipment is easy to install, use, operate, and maintain; The characteristics of stable operation, energy conservation, environmental protection, and high degree of automation

Outlet: NPT3/4 ″

water tank

The water tank is divided into a clean water tank and a raw water tank, both of which are made of 304 stainless steel. The total effective volume of the water tank is ≥ 4.5m ³

Number of configured clean water tanks: 1, with a capacity of ≥ 1.5m ³ , Internally, it is treated with drinking water through water purification equipment;

Number of configured raw water tanks: 1 unit, with a capacity of ≥ 3m ³ , Internally, there are three types of surface water;

The boxes are all welded from 304 stainless steel plates. The top of the box is equipped with an opening that can serve as a water filling hole for injecting water into the box. The hole cover and opening are sealed with rubber rings and connected with bolts;

There are 3-4 folding wave guards inside the box. The box is equipped with inlet filtration, outlet filtration, overflow, and sewage discharge devices;

A drainage outlet is set at the lowest point of the water tank to ensure that the water in the tank can be discharged completely during storage;

Keystone Vessel Industrial Gas Cylinders| ISO Tank| Pressure Vessel| UN Portable Tanks- Dong Runze Special Vehicle

ISUZU GIGA Water Purification Vehicle

Army Portable Water Treatment Units  Water Purification Vehicle Truck mounted Purification System Equipment Vehicle

Water Purification Vehicle Truck mounted Purification System Equipment Vehicle

ISUZU GIGA Chassis 6x4 QL1251FTFZY

Special Vehicle Overall Size 9480,11585,10165 x 2540 x 3800 (mm)

Chassis | Chassis Model | QL1251FTFZY |

Wheelbase | 4650+1350 mm 4650+1370,5700+1370,5100+1370mm | |

Gross Weight | 25000kgs | |

Curb Weight | 14500kgs | |

Engine | Engine Model | 6HK1-TCG60 ,221 KW/301HP |

Type | Multi cylinder, 4stroke, 6-cylinder water cooled, direct fuel injection, turbo-diesel engine. | |

Displacement Volume(ml) | 7790 | |

Net Power(KW) | Min 300 HP at rated RPM | |

Fuel Type | Diesel | |

Emission Standard | Eour 6 | |

Clutch System | Model | Single Plate, dry friction |

Steering System | Power Steering | Left hand driving, |

Transmission System | Manually Operated | RT-11509C |

Brake System | Service Brake | Hydraulic disk brakes |

Park Brake | Air Brake & Hand Brake | |

Suspension System(Front & Rear) | Semi-elliptical leaf spring with telessopic shock absorber (both front & rear) | |

Type | Type Quantity | 10 pcs |

Type Specification | 295/80R22.5 18PR | |

Cabin | The cabine of 3 person (including driver), cruise control, ABS, air conditgioning, electric glass, adjustable headlights, USB, etc. | |

unpurified water tank | Tank Capacity | 3 m³ |

Tank Material | SS304 Stainless steel | |

Purified Water tank | Tank Capacity | 1.5 m³ |

Tank Material | SS304 Stainless steel | |

PTO | PTO power take-off take | |

Paint | Tank color is according to client’s requirements. | |

Thermal insulation of large board car: the total heat transfer coefficient of the car is less than 2.5 W/m2 · ℃

The wall panels of the large carriage are of sandwich structure

The inner and outer skins are 1.2mm aluminum plates, and the middle is rigid polyurethane foam sandwich layer and aluminum profile reinforced beam skin, aluminum alloy skeleton and polyurethane foam, which are bonded with special large plate adhesive, and then hot pressed once by the large plate press

Wall panel thickness 51.4mm

High temperature resistance of wall panels: can withstand high temperatures of 70 ℃ without degumming;

Low temperature resistance of wall panels: can withstand -55 ℃ low temperature without degumming;

Sunlight resistance of wall panel: under the condition of 1120w/m2 of radiant intensity, deformation, stickiness, cracking, damage, etc. will not occur;

Mold resistance of wall panels: able to withstand the harmful effects of various molds and fungi;

Humidity resistance of wall panels: able to withstand a relative humidity of no more than 95% (40 ℃);

Salt spray corrosion resistance of wall panels: able to resist the harmful effects of salt spray corrosion environment in coastal areas of China;

Wall panel flame retardancy: It has flame retardancy and can self extinguish when left on fire;

Environmental friendliness of wall panels: meeting E0 level environmental protection requirements

The large plate structure has good airtightness (water and air tightness), thermal insulation, sound insulation, waterproof, fireproof, heat radiation resistant, salt spray corrosion resistant, insect resistant, and other performance; By optimizing the reasonable layout of the skeleton and the design of the skeleton structure, the optimal values between the stiffness, strength, and weight of each board are achieved, which not only ensures the overall strength, stiffness, and weight requirements of the car body, but also achieves the goals of thermal insulation and sound insulation, fully reflecting the superiority of the large board car. When designing, full consideration should be given to the requirements for thermal insulation performance. Heat blocking should be installed at all skeleton positions inside the large panel to reduce heat loss in the carriage and improve the thermal insulation performance of the carriage

The carriage has sufficient strength and stiffness to withstand the vibrations and impacts of the car during operation. The structure of the large panel shelter complies with GJB6109-2007 "General Specification for Military Shelters"

The boards of the carriage are connected by riveting and high-strength bolts to form a whole, ensuring that the carriage has sufficient strength and stiffness to withstand the vibration and impact of the car during driving. The structure of the large board is shown in the following figure. All openings should be sealed; All cables and pipelines are sealed with insulation

Both the inner and outer skins are made of aluminum alloy, a thin sheet of aluminum, and anodized. The carriage wall panel has good sealing, heat insulation, and good strength and stiffness. The pressing of the carriage wall panel is controlled using our factory's typical process, and the structural design is carried out in accordance with GJB5113 "General Specification for Logistics Box Cars" to ensure that after various tests, the surface and structural components of the carriage are free from defects such as bending, warping, fracture, delamination, detachment, damage, damage, and permanent deformation.

Wall panel flatness: 1600mm × Within the range of 700mm, the flatness error shall not exceed 1.5mm,

Wall panel strength: can withstand uniformly distributed static load: ≥ 2kN/m2; Concentrated static load: area of 300mm × 600mm, static

Load ≥ 3kN.

Painting treatment of the interior surface of the car

The interior floor of the carriage is made of patterned aluminum plates

heater

Rated pressure: ≥ 0.7 MPa;

Wire section requirements: 6 square millimetre

Overall dimensions (length × wide × Height: ≤ 410x260x70 mm;

Net weight: ≤ 3.3 kilograms

Rated power: ≤ 8500W;

Rated voltage: 220V;

Operation mode: touch control;

Applicable number of people: ≥ 4 or more

Small generator

Rated power: ≥ 3KW

Backup power: ≥ 3 2KW

Rated frequency: 50HZ

Rated voltage: 380V

Structure type: open frame/hand push type

Power factor: 1.0

Number of phases: single-phase/three-phase

DC output: ≥ 12-8.3 (V-A)

Working time: ≥ 8H

Machine weight: ≤ 77kg

External dimensions: ≤ 660 * 550 * 600mm

Water purifier

Net water flow rate: ≥ 1000L/h (25 ℃);

Suitable water quality: surface water of three types;

Effluent quality: drinking water standard;

Overall dimensions (length × wide × Height: ≤ 1750mm × 800mm × 1700mm;

Weight: ≤ 750kg.

The system adopts a "pre-treatment+single stage reverse osmosis" water treatment process, with a reasonable design, stable operation, and water production quality that meets the requirements.

The equipment is easy to install, use, operate, and maintain; The characteristics of stable operation, energy conservation, environmental protection, and high degree of automation

Outlet: NPT3/4 ″

water tank

The water tank is divided into a clean water tank and a raw water tank, both of which are made of 304 stainless steel. The total effective volume of the water tank is ≥ 4.5m ³

Number of configured clean water tanks: 1, with a capacity of ≥ 1.5m ³ , Internally, it is treated with drinking water through water purification equipment;

Number of configured raw water tanks: 1 unit, with a capacity of ≥ 3m ³ , Internally, there are three types of surface water;

The boxes are all welded from 304 stainless steel plates. The top of the box is equipped with an opening that can serve as a water filling hole for injecting water into the box. The hole cover and opening are sealed with rubber rings and connected with bolts;

There are 3-4 folding wave guards inside the box. The box is equipped with inlet filtration, outlet filtration, overflow, and sewage discharge devices;

A drainage outlet is set at the lowest point of the water tank to ensure that the water in the tank can be discharged completely during storage;

Keystone Vessel Industrial Gas Cylinders| ISO Tank| Pressure Vessel| UN Portable Tanks- Dong Runze Special Vehicle

Related Products

SUCCESS CASES

More >>- 2026-02-013PCS T7 PE Lined ISO Tank Container for Potassium Hydroxide KOH, HCL Hydrochloric Acid, Hydrogen Peroxide for India

3PCS T7 PE Lined ISO Tank Container for Potassium Hydroxide KOH, HCL Hydrochloric Acid, Hydrogen Peroxide for India DTAU2601014 DTAU2601020 DTAU2601035 Vessel/Voyage:SHUN GANG CHANG JIE V.L2602E B/L Date: FEB. 01,2026 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2026-01-16T14 T7 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) , Potassium Hydroxide KOH, HCL Hydrochloric Acid, for India

T14 T7 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India DTAU2512010 DTAU2512025 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2025-12-1212KL Polyethylene PE Lined Tank Body for Hydrochloric Acid HCL Cargo Truck To Vietnam

12KL Polyethylene PE Lined Tank Body for Hydrochloric Acid HCL Cargo Truck To Vietnam

- 2025-11-11T7 T14 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India

T7 T14 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India DHF, HCL,KOH , H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide 20FT TANK CONTAINER (EMPTY AND NEW TANKS) DTAU2509090 DTAU2509103 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2025-09-28Advantages And Disadvantages of Different Material Storage T8 T14 PE / PTFE Lined ISO Tank Container for Electronic Grade Hydrogen Peroxide (H₂O₂) HCL,KOH

Advantages And Disadvantages of Different Material Storage T8 T14 PE / PTFE Lined ISO Tank Container for Electronic Grade Hydrogen Peroxide (H₂O₂) DTAU2509016 DTAU2509021 DTAU2509037

- 2025-09-016PCS T7 T14 PE Lined ISO Tank Container for HCL, PAC Hydrochloric Acid / Chemical Poly Aluminum Chloride 21KL To Vietnam

6PCS T7 T14 PE Lined ISO Tank Container for HCL, PAC Hydrochloric Acid / Chemical Poly Aluminum Chloride 21KL To Vietnam road transport type PE Lined Tank Used to contain: HCl , NaOH , PAC , H2SO4(max 98%) etc. Tank Capacity: 21,000 Liters 21m3 Steel sheet 6mm, head 6mm Liner thickness: 16mm PE 20 FT TANK (EMPTY AND NEW TANKS) HCDA2505016 HCDA2505021 HCDA2505037 HCDA2505042 HCDA2505058 HCDA2505063

- 2025-08-293 Units PE Lined T7 T8 T14 ISO Tank Container for DHF,HCL,KOH,H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide Export To India

3 Units PE Lined T7 T8 T14 ISO Tank Container for DHF,HCL,KOH,H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide Export To India DTAU2508010 DTAU2508025 DTAU2508030 20FT TANK CONTAINER (EMPTY AND NEW TANKS)

- 2025-06-1820PCS UN 3394 3399 Portable Tanks C-480 TMA Cylinders to USA

20PCS UN 3394 3399 Portable Tanks C-480 TMA Cylinders to USA PORTABLE TANK (EMPTY AND NEW TANKS) C-480 CYLINDER HS:860900.00(USA) Adr/Rid Organometallic Substance, Liquid, Water- Reactive C-480 Saddle Type Portable Tank, tank capacity 1880L KS1880-T21 Portable Tanks ASME Test DATA Report(C250051-C250070) BV Certificate No.:IIC-BVCT2570036S KSVU 250051 -70 Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg

- 2025-04-034 Units T14 ISO Tank Container PE Lined for Hydrofluoric HF Hydrochloric Acid HCL, Ferric Chloride Potassium Hydroxide KOH Tank Container Export To India

4 Units T14 ISO Tank Container PE Lined for Hydrofluoric HF Hydrochloric Acid HCL, Ferric Chloride Potassium Hydroxide KOH Tank Container Export To India DTAU2502011 DTAU2502027 DTAU2502032 DTAU2502048 20 FT TANK CONTAINER FOR HYDROCHLORIC ACID UN1789 HCL, HYDROFLUORIC ACID UN1790 HF ACID CARON STEEL AND LINED WITH 16MM LLDPE TANKS CAPACITY 21 KL FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, TOP UNLOADING TARE WEIGHT 5200KG 1UNIT 20FT TANK CONTAINER FOR UN1814 KOH POTASSIUM HYDROXIDE 45% SOLUTION DISH HEAD TYPE TANK CAPACITY: 19000LITERS FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, BOTTOM UNLOADING TARE WEIGHT 5300KG 1UNIT 20FT TANK CONTAINER FOR UN2014 H2O2 HYDROGEN PEROXIDE 31% SOLUTION DISH HEAD TYPE TANK CAPACITY: 19000LITERS FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, BOTTOM UNLOADING TARE WEIGHT 5300KG 2UNITS

- 2025-04-01Steel Lined PE Plastic ISO Tank for Hydrochloric Acid HCL12KL,15KL/16KL/19KL/22KL To Vietnam

Steel Lined PE Plastic ISO Tank for Hydrochloric Acid HCL12KL,15KL/16KL/19KL/22KL To Vietnam Description of goods Quantity N.W PE LINED STEEL TANK 5100X 2350 X 1400MM / 12.5M3 (EMPTY AND NEW TANKS) MODEL: DTA5212 HS CODE : 7309000000 、6300KGS PE LINED STEEL TANK 6040 X 2400 X 1600MM / 15.8M3 (EMPTY AND NEW TANKS) MODEL: DTA5215 HS CODE : 7309000000 1 3650KG PE LINED STEEL TANK 7190 X 2300X 1300MM / 16.2M3 (EMPTY AND NEW TANKS) MODEL: DTA5316 HS CODE : 7309000000 、4350KG PE LINED STEEL TANK 8520 X 2260 X 1350MM / 19.5M3 (EMPTY AND NEW TANKS) MODEL: DTA5319 HS CODE : 7309000000 、4850KG 20 FT TANK CONTAINER 6058X2438X2591MM / 22.8M3 (EMPTY AND NEW TANKS) MODEL: DTAU2501015 、5800KG

- 2025-02-261000L SS304 Stainless Steel Lined PE Plastic Tank for Hydrochloric Acid to GUAYAQUIL, EC

1000L SS304 Stainless Steel Lined PE Plastic Tank for Hydrochloric Acid to GUAYAQUIL, EC STORAGE TANK 304 STAINLESS STEEL LINED PLASTIC TANK VERTICAL TANK STAINLESS STEEL 304 THICKNESS 5MM+PE 16MM CAPACITY: 1,000 L RESIST 15%~38% HYDROCHLORIC ACID HS CODE:730900

- 2025-01-1920PCS Metal Alky TEAL C480 T21 UN Portable Tank Cylinders To USA

20Units UN T21 Portable Tank Container 1880L Cylinder For TEAL Metal Alkyls UN3394 UN3399 to USA with 30pcs Spare PSV RELIEF VALVES SF/A412F-25P(3B) Manufacturer (SHENYANG XINGUANG VALVE ) KS1880-T21 Portable Tanks Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg KSVU240016 -KSVU240035 Adr/Rid Organometallic Substance, Liquid, Water- Reactive C-480 Saddle Type Portable Tank, tank capacity 1880L

- 2024-12-206 Sets Thermal Insulated LLDPE Lined Tanks 25KL for Sodium Hypochlorite Hydrochloric Acid Storage Transport Tanker To Saudi Arabia

6 Sets Thermal Insulated LLDPE Lined Tanks 25KL for Sodium Hypochlorite Hydrochloric Acid To Saudi Arabia Lined PE Tanks 6604Gallon For Truck Trailer mounted FROM WUHAN PORT CHINA TO DAMMAM, SAUDI ARABIA BY SEA. + Port of loading : WUHAN PORT + Port of unloading :DAMMAM SAUDI ARABIA

- 2024-12-022 Units T14 Hydrofluoric Hydrochloric Acid UN1789 UN1790 ISOTank Container Road Transport For ASCOR

2 Units T14 Hydrofluoric Hydrochloric Acid UN1789 UN1790 ISOTank Container Road Transport For ASCOR 20FT Tank Container (EMPTY AND NEW TANKS) FOR HYDROCHLORIC ACID UN1789 HCL HYDROFLUORIC ACID HF ACID UN1790 CARBON STEEL AND LINED WITH 16MM LLDPE DTAU2404015, DTAU2404020

- 2024-10-245 Units C480 Keystone Vessel T21 TEAL Cylinder UN Portable Tanks To SAUDI ARABIA

5 Units Keystone Vessel T21 TEAL UN Portable Tank C480 Cylinder To SAUDI ARABIA KS1880-T21 Portable Tanks Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg KSVU2400114 KSVU2400120 KSVU2400135 KSVU2400140 KSVU2400156