Special Vehicles

- Aerial platform truck

- Dolly Trailer

- ISO Tank

- Recovery Trucks

- Road Sweeper

- SKD Truck Body

- Special Vehicle

- Tank Trailer

- Tank Truck

- Truck Accessories Parts

- All Wheel Drive off road truck

- Beiben truck Customizing

- Body parts

- Concrete mixer trucks

- Crane truck

- Environmental Trucks

- Fire Trucks

- ISUZU UD HINO Truck Customizing

- IVECO FOTON-FAW JAC Customizing

- Portable Tank Container

- Recovery Trucks Wrecker

- Road tanker

- SHACMAN Truck Customizing

- Special Car

- storage tank

- Machinery

- PPE

Wechat: +8615271357675

MOB: 86-152-71357675

ADD: NO.1 TAIZONG AVENUE GAOQIAO INDUSTRY PARK TAIWANESE INVESTMENT AREA DONGXIHU DISTRICT WUHAN CITY, HUBEI PROVINCE, P.R CHINA

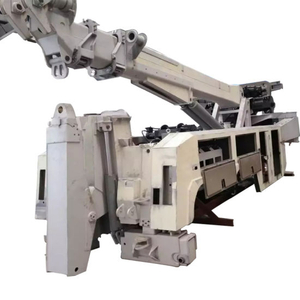

Customizing Truck Upper Body Hydraulic Garbage Compactor SKD 4cbm - 20cbm

| Availability: | |

|---|---|

| Quantity: | |

-

Shanghai, China

-

3000

-

T/T

Customizing Hydraulic Garbage Compactor Truck Body SKD 4cbm - 20cbm

Cell /+8615271357675

The pictures are for your reference only.

Compactor garbage truck information :

Refuse compactor structure parameters | |

Equipment | |

Structure | Body, sub frame, lifting rear part, the loading device, the pushing-out plate, hydraulic and electric systems |

Loading capacity | 8m3,10m3,-20m3 |

System of loading | Mechanized, rear loading |

Modes of the pressing | Manual,semi-automatic,automatic,lifting rear part operation manual,loading,pushing,pressing, pushing out automatic |

Body | |

Version | All-metal |

Shape | arc-shaped |

Sidewalls | Q345 Sheet carbon steel (thickness: 4mm) |

Bottom | Q345 Sheet carbon steel (thickness: 4 mm) |

Roof | Q345 Sheet carbon steel (thickness: 4 mm) |

Front frame | Q345 Sheet carbonaceous steel (thickness: 5 mm) |

Rear frame | n-shaped profile from sheet carbon steel (thickness:5 mm) |

Basis | 120x120mm (thickness: 5 mm) |

Loading bunker | |

Loading bunker | All-metal with sidewalls and a loading ladle |

Volume | 1.0 m3 |

Sidewalls | Q345 Sheet carbon steel (thickness: 6 mm) |

Scraper&pushing-out plate | Q345 Sheet carbon steel (thickness: 8 mm) |

Liquid drain | Drainage channel,sewage tank |

Working zone Lighting | 2 lamps |

Mechanism of raising | Two hydraulic cylinders |

Ensuring tightness | Between the body and lifting back part in the lower part profile acid-proof rubber is used. |

Pressing system | |

Features | Control mode diversification,bidirectional compression |

Pressure | 16Mpa |

Compaction ratio | 4.0:1 |

Loading cycle | 25-30 second |

Unloading cycle | 25-35 second |

pressing mechanism | The giving plate and hinge related pressing plate moving on two directing bars |

Pressing mode | Automatic pressing (1 full cycle and continuous pressing) and controlling of each cycle of pressing separately |

Control of pressing | Control from the external panel on the bunker |

Lifting rear part | |

Mechanism of lifting | Two hydraulic cylinders |

Function description | Suitable for various rubbish bins |

Others | |

Color and Logo | Optional |

Standard configuration | Chassis,arc-shaped body,sub frame,rear lifting part,loading bunker,pushing-out plate,hydraulic system,pressing system,sewage tank,climbing ladder,pneumatic control,PLC electric automatic control. |

Selective configuration | multifunctional rear lifting part,rear handrail and footplate,other shapes of body,rear swing arm,and etc. |

1.Upper unit installed on the chassis ,connection part is longitudinal beams on rubber pads

2.Exhaust plate in the front wall of the body ,and a rear side with a press mechanism

3.Three type of body shape .Bottom plate is reinforced by longitudinal beams

4.Push -out board is supported of the telescopic cylinder

5.Foot board &handle for maintain pipeline on the roof

6.Fluoro plastic slider for push-out plate

7.The rear hopper made of high quality steel and 6mm thickness ,mechanically and manually load the bucket ,raised by two cylinder

8.Hydraulic valve &plc made in Japan ,automatically distribute hydraulic oil to the cylinder as working status

9.The pressing mechanism works in automatic ,semi-automatic and manual modes . operation can single or chitinous

10.Colour & pattern as required

11.An additional push-button control unit in cab ,and buzzer in the cab for keep in touch with the operator at the rear of the garbage truck

12.Two button at the side of the body for emergency stopping

13.Spare switch ensure the operation continue going when the vehicle has malfunction

14.More kinds of lifting device

15.Safety road,monitor ,caution sign

16.Rear door ,front door ,lock hook

17.Leak proof device---no dirty water leak& omit

| Wheelbase we use | 3300 mm , 3360 mm,4500mm,5100mm,..... |

| Compactor capacity | 6000 Liter |

| Sewage water tank | 250 L |

| Material | High strength carbon steel |

| Horsepower advice | 120 hp |

| Voltage of chassis battery | 12V / 24 V |

| Truck body equipment | |

| Equipment | 1.Equipped with hermetic dustbin,hydraulic systerm and operation system 2.Automatic compress and uninstall,sewage can be collected by the dump tank. 3.Pressure is large,leakproofness is good,operation is convenient and security is demendable 4:waste water tanker 160Liters 5:truck wheelbase:4500mm Garbage body Material: 16 Low alloy steel Garbage boday welding by 8mm,5mm,4mm and 16Mnr steel Hydraulic system : Electric magnetic valve TG3522-02U Cylinder :MAL25X50 Combination valve: 34DLS-10-P-0000 Lift bin oil cylinder: HSGK01-63/35-700X450 Push plate oil cylinder : DJG-150III-1150X2170 Scraper plate oil cylinder:HSGK01-80/45-700X300 Sliding plate oil cylinder:DJG-115II-1000X1020 The negative pressure oil cylinder:HSGK01-63/35-500X300 Lifting bin oil cylinder: HSKG01-90/63-832X500 Hydraulic oil fliter :ZUT-A63X20 Stop valve:Q11F-16P Hydraulic oil pump :CBT-F532FHL Hydraulic gauge:YN-60 40Mpa Air cleaner: TW2000-02U Air pressure gauge : 0- 1.0mpA |

5CBM Compactor garbage truck body

| Overall dimension(mm) | 4330×1856×2289 | |

| Compactor Body | Body dimensions(mm) | 2170×1730×1330 |

| Volume | 5M3 | |

| Body Floor steel | 5mm manganese steel | |

| Body Roof steel | 4.5mm manganese steel | |

| Body Side Plate steel | 4.5mm manganese steel | |

| Ejection Plate steel | Ejection Plate steel | |

| Hydraulic valve | Imported Japan | |

| Water Tank | Volume | 150-600L |

| Material | stainless steel | |

| Hopper | Volume | 1M3 |

| Hopper Loading Height | 920mm | |

| Side Plate steel | 5mm | |

| Floor Plate steel | 5+3mm | |

| Press Plate steel | 3& 5mm | |

| Safety | 2 Pcs safety bars for hopper | |

| Working Specification | Control mode | Automatic +Manual |

| Compaction ratio | 1:3 | |

| Time for single loading cycle | 10-11s | |

| Time for single discharge cycle | <18s | |

| Max broke force of compression | 16T |

Cell :+8615271357675

Customizing Hydraulic Garbage Compactor Truck Body SKD 4cbm - 20cbm

Cell /+8615271357675

The pictures are for your reference only.

Compactor garbage truck information :

Refuse compactor structure parameters | |

Equipment | |

Structure | Body, sub frame, lifting rear part, the loading device, the pushing-out plate, hydraulic and electric systems |

Loading capacity | 8m3,10m3,-20m3 |

System of loading | Mechanized, rear loading |

Modes of the pressing | Manual,semi-automatic,automatic,lifting rear part operation manual,loading,pushing,pressing, pushing out automatic |

Body | |

Version | All-metal |

Shape | arc-shaped |

Sidewalls | Q345 Sheet carbon steel (thickness: 4mm) |

Bottom | Q345 Sheet carbon steel (thickness: 4 mm) |

Roof | Q345 Sheet carbon steel (thickness: 4 mm) |

Front frame | Q345 Sheet carbonaceous steel (thickness: 5 mm) |

Rear frame | n-shaped profile from sheet carbon steel (thickness:5 mm) |

Basis | 120x120mm (thickness: 5 mm) |

Loading bunker | |

Loading bunker | All-metal with sidewalls and a loading ladle |

Volume | 1.0 m3 |

Sidewalls | Q345 Sheet carbon steel (thickness: 6 mm) |

Scraper&pushing-out plate | Q345 Sheet carbon steel (thickness: 8 mm) |

Liquid drain | Drainage channel,sewage tank |

Working zone Lighting | 2 lamps |

Mechanism of raising | Two hydraulic cylinders |

Ensuring tightness | Between the body and lifting back part in the lower part profile acid-proof rubber is used. |

Pressing system | |

Features | Control mode diversification,bidirectional compression |

Pressure | 16Mpa |

Compaction ratio | 4.0:1 |

Loading cycle | 25-30 second |

Unloading cycle | 25-35 second |

pressing mechanism | The giving plate and hinge related pressing plate moving on two directing bars |

Pressing mode | Automatic pressing (1 full cycle and continuous pressing) and controlling of each cycle of pressing separately |

Control of pressing | Control from the external panel on the bunker |

Lifting rear part | |

Mechanism of lifting | Two hydraulic cylinders |

Function description | Suitable for various rubbish bins |

Others | |

Color and Logo | Optional |

Standard configuration | Chassis,arc-shaped body,sub frame,rear lifting part,loading bunker,pushing-out plate,hydraulic system,pressing system,sewage tank,climbing ladder,pneumatic control,PLC electric automatic control. |

Selective configuration | multifunctional rear lifting part,rear handrail and footplate,other shapes of body,rear swing arm,and etc. |

1.Upper unit installed on the chassis ,connection part is longitudinal beams on rubber pads

2.Exhaust plate in the front wall of the body ,and a rear side with a press mechanism

3.Three type of body shape .Bottom plate is reinforced by longitudinal beams

4.Push -out board is supported of the telescopic cylinder

5.Foot board &handle for maintain pipeline on the roof

6.Fluoro plastic slider for push-out plate

7.The rear hopper made of high quality steel and 6mm thickness ,mechanically and manually load the bucket ,raised by two cylinder

8.Hydraulic valve &plc made in Japan ,automatically distribute hydraulic oil to the cylinder as working status

9.The pressing mechanism works in automatic ,semi-automatic and manual modes . operation can single or chitinous

10.Colour & pattern as required

11.An additional push-button control unit in cab ,and buzzer in the cab for keep in touch with the operator at the rear of the garbage truck

12.Two button at the side of the body for emergency stopping

13.Spare switch ensure the operation continue going when the vehicle has malfunction

14.More kinds of lifting device

15.Safety road,monitor ,caution sign

16.Rear door ,front door ,lock hook

17.Leak proof device---no dirty water leak& omit

| Wheelbase we use | 3300 mm , 3360 mm,4500mm,5100mm,..... |

| Compactor capacity | 6000 Liter |

| Sewage water tank | 250 L |

| Material | High strength carbon steel |

| Horsepower advice | 120 hp |

| Voltage of chassis battery | 12V / 24 V |

| Truck body equipment | |

| Equipment | 1.Equipped with hermetic dustbin,hydraulic systerm and operation system 2.Automatic compress and uninstall,sewage can be collected by the dump tank. 3.Pressure is large,leakproofness is good,operation is convenient and security is demendable 4:waste water tanker 160Liters 5:truck wheelbase:4500mm Garbage body Material: 16 Low alloy steel Garbage boday welding by 8mm,5mm,4mm and 16Mnr steel Hydraulic system : Electric magnetic valve TG3522-02U Cylinder :MAL25X50 Combination valve: 34DLS-10-P-0000 Lift bin oil cylinder: HSGK01-63/35-700X450 Push plate oil cylinder : DJG-150III-1150X2170 Scraper plate oil cylinder:HSGK01-80/45-700X300 Sliding plate oil cylinder:DJG-115II-1000X1020 The negative pressure oil cylinder:HSGK01-63/35-500X300 Lifting bin oil cylinder: HSKG01-90/63-832X500 Hydraulic oil fliter :ZUT-A63X20 Stop valve:Q11F-16P Hydraulic oil pump :CBT-F532FHL Hydraulic gauge:YN-60 40Mpa Air cleaner: TW2000-02U Air pressure gauge : 0- 1.0mpA |

5CBM Compactor garbage truck body

| Overall dimension(mm) | 4330×1856×2289 | |

| Compactor Body | Body dimensions(mm) | 2170×1730×1330 |

| Volume | 5M3 | |

| Body Floor steel | 5mm manganese steel | |

| Body Roof steel | 4.5mm manganese steel | |

| Body Side Plate steel | 4.5mm manganese steel | |

| Ejection Plate steel | Ejection Plate steel | |

| Hydraulic valve | Imported Japan | |

| Water Tank | Volume | 150-600L |

| Material | stainless steel | |

| Hopper | Volume | 1M3 |

| Hopper Loading Height | 920mm | |

| Side Plate steel | 5mm | |

| Floor Plate steel | 5+3mm | |

| Press Plate steel | 3& 5mm | |

| Safety | 2 Pcs safety bars for hopper | |

| Working Specification | Control mode | Automatic +Manual |

| Compaction ratio | 1:3 | |

| Time for single loading cycle | 10-11s | |

| Time for single discharge cycle | <18s | |

| Max broke force of compression | 16T |

Cell :+8615271357675

Related Products

SUCCESS CASES

More >>- 2026-02-013PCS T7 PE Lined ISO Tank Container for Potassium Hydroxide KOH, HCL Hydrochloric Acid, Hydrogen Peroxide for India

3PCS T7 PE Lined ISO Tank Container for Potassium Hydroxide KOH, HCL Hydrochloric Acid, Hydrogen Peroxide for India DTAU2601014 DTAU2601020 DTAU2601035 Vessel/Voyage:SHUN GANG CHANG JIE V.L2602E B/L Date: FEB. 01,2026 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2026-01-16T14 T7 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) , Potassium Hydroxide KOH, HCL Hydrochloric Acid, for India

T14 T7 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India DTAU2512010 DTAU2512025 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2025-12-1212KL Polyethylene PE Lined Tank Body for Hydrochloric Acid HCL Cargo Truck To Vietnam

12KL Polyethylene PE Lined Tank Body for Hydrochloric Acid HCL Cargo Truck To Vietnam

- 2025-11-11T7 T14 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India

T7 T14 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India DHF, HCL,KOH , H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide 20FT TANK CONTAINER (EMPTY AND NEW TANKS) DTAU2509090 DTAU2509103 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2025-09-28Advantages And Disadvantages of Different Material Storage T8 T14 PE / PTFE Lined ISO Tank Container for Electronic Grade Hydrogen Peroxide (H₂O₂) HCL,KOH

Advantages And Disadvantages of Different Material Storage T8 T14 PE / PTFE Lined ISO Tank Container for Electronic Grade Hydrogen Peroxide (H₂O₂) DTAU2509016 DTAU2509021 DTAU2509037

- 2025-09-016PCS T7 T14 PE Lined ISO Tank Container for HCL, PAC Hydrochloric Acid / Chemical Poly Aluminum Chloride 21KL To Vietnam

6PCS T7 T14 PE Lined ISO Tank Container for HCL, PAC Hydrochloric Acid / Chemical Poly Aluminum Chloride 21KL To Vietnam road transport type PE Lined Tank Used to contain: HCl , NaOH , PAC , H2SO4(max 98%) etc. Tank Capacity: 21,000 Liters 21m3 Steel sheet 6mm, head 6mm Liner thickness: 16mm PE 20 FT TANK (EMPTY AND NEW TANKS) HCDA2505016 HCDA2505021 HCDA2505037 HCDA2505042 HCDA2505058 HCDA2505063

- 2025-08-293 Units PE Lined T7 T8 T14 ISO Tank Container for DHF,HCL,KOH,H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide Export To India

3 Units PE Lined T7 T8 T14 ISO Tank Container for DHF,HCL,KOH,H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide Export To India DTAU2508010 DTAU2508025 DTAU2508030 20FT TANK CONTAINER (EMPTY AND NEW TANKS)

- 2025-06-1820PCS UN 3394 3399 Portable Tanks C-480 TMA Cylinders to USA

20PCS UN 3394 3399 Portable Tanks C-480 TMA Cylinders to USA PORTABLE TANK (EMPTY AND NEW TANKS) C-480 CYLINDER HS:860900.00(USA) Adr/Rid Organometallic Substance, Liquid, Water- Reactive C-480 Saddle Type Portable Tank, tank capacity 1880L KS1880-T21 Portable Tanks ASME Test DATA Report(C250051-C250070) BV Certificate No.:IIC-BVCT2570036S KSVU 250051 -70 Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg

- 2025-04-034 Units T14 ISO Tank Container PE Lined for Hydrofluoric HF Hydrochloric Acid HCL, Ferric Chloride Potassium Hydroxide KOH Tank Container Export To India

4 Units T14 ISO Tank Container PE Lined for Hydrofluoric HF Hydrochloric Acid HCL, Ferric Chloride Potassium Hydroxide KOH Tank Container Export To India DTAU2502011 DTAU2502027 DTAU2502032 DTAU2502048 20 FT TANK CONTAINER FOR HYDROCHLORIC ACID UN1789 HCL, HYDROFLUORIC ACID UN1790 HF ACID CARON STEEL AND LINED WITH 16MM LLDPE TANKS CAPACITY 21 KL FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, TOP UNLOADING TARE WEIGHT 5200KG 1UNIT 20FT TANK CONTAINER FOR UN1814 KOH POTASSIUM HYDROXIDE 45% SOLUTION DISH HEAD TYPE TANK CAPACITY: 19000LITERS FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, BOTTOM UNLOADING TARE WEIGHT 5300KG 1UNIT 20FT TANK CONTAINER FOR UN2014 H2O2 HYDROGEN PEROXIDE 31% SOLUTION DISH HEAD TYPE TANK CAPACITY: 19000LITERS FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, BOTTOM UNLOADING TARE WEIGHT 5300KG 2UNITS

- 2025-04-01Steel Lined PE Plastic ISO Tank for Hydrochloric Acid HCL12KL,15KL/16KL/19KL/22KL To Vietnam

Steel Lined PE Plastic ISO Tank for Hydrochloric Acid HCL12KL,15KL/16KL/19KL/22KL To Vietnam Description of goods Quantity N.W PE LINED STEEL TANK 5100X 2350 X 1400MM / 12.5M3 (EMPTY AND NEW TANKS) MODEL: DTA5212 HS CODE : 7309000000 、6300KGS PE LINED STEEL TANK 6040 X 2400 X 1600MM / 15.8M3 (EMPTY AND NEW TANKS) MODEL: DTA5215 HS CODE : 7309000000 1 3650KG PE LINED STEEL TANK 7190 X 2300X 1300MM / 16.2M3 (EMPTY AND NEW TANKS) MODEL: DTA5316 HS CODE : 7309000000 、4350KG PE LINED STEEL TANK 8520 X 2260 X 1350MM / 19.5M3 (EMPTY AND NEW TANKS) MODEL: DTA5319 HS CODE : 7309000000 、4850KG 20 FT TANK CONTAINER 6058X2438X2591MM / 22.8M3 (EMPTY AND NEW TANKS) MODEL: DTAU2501015 、5800KG

- 2025-02-261000L SS304 Stainless Steel Lined PE Plastic Tank for Hydrochloric Acid to GUAYAQUIL, EC

1000L SS304 Stainless Steel Lined PE Plastic Tank for Hydrochloric Acid to GUAYAQUIL, EC STORAGE TANK 304 STAINLESS STEEL LINED PLASTIC TANK VERTICAL TANK STAINLESS STEEL 304 THICKNESS 5MM+PE 16MM CAPACITY: 1,000 L RESIST 15%~38% HYDROCHLORIC ACID HS CODE:730900

- 2025-01-1920PCS Metal Alky TEAL C480 T21 UN Portable Tank Cylinders To USA

20Units UN T21 Portable Tank Container 1880L Cylinder For TEAL Metal Alkyls UN3394 UN3399 to USA with 30pcs Spare PSV RELIEF VALVES SF/A412F-25P(3B) Manufacturer (SHENYANG XINGUANG VALVE ) KS1880-T21 Portable Tanks Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg KSVU240016 -KSVU240035 Adr/Rid Organometallic Substance, Liquid, Water- Reactive C-480 Saddle Type Portable Tank, tank capacity 1880L

- 2024-12-206 Sets Thermal Insulated LLDPE Lined Tanks 25KL for Sodium Hypochlorite Hydrochloric Acid Storage Transport Tanker To Saudi Arabia

6 Sets Thermal Insulated LLDPE Lined Tanks 25KL for Sodium Hypochlorite Hydrochloric Acid To Saudi Arabia Lined PE Tanks 6604Gallon For Truck Trailer mounted FROM WUHAN PORT CHINA TO DAMMAM, SAUDI ARABIA BY SEA. + Port of loading : WUHAN PORT + Port of unloading :DAMMAM SAUDI ARABIA

- 2024-12-022 Units T14 Hydrofluoric Hydrochloric Acid UN1789 UN1790 ISOTank Container Road Transport For ASCOR

2 Units T14 Hydrofluoric Hydrochloric Acid UN1789 UN1790 ISOTank Container Road Transport For ASCOR 20FT Tank Container (EMPTY AND NEW TANKS) FOR HYDROCHLORIC ACID UN1789 HCL HYDROFLUORIC ACID HF ACID UN1790 CARBON STEEL AND LINED WITH 16MM LLDPE DTAU2404015, DTAU2404020

- 2024-10-245 Units C480 Keystone Vessel T21 TEAL Cylinder UN Portable Tanks To SAUDI ARABIA

5 Units Keystone Vessel T21 TEAL UN Portable Tank C480 Cylinder To SAUDI ARABIA KS1880-T21 Portable Tanks Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg KSVU2400114 KSVU2400120 KSVU2400135 KSVU2400140 KSVU2400156