Special Vehicles

- Aerial platform truck

- Dolly Trailer

- ISO Tank

- Recovery Trucks

- Road Sweeper

- SKD Truck Body

- Special Vehicle

- Tank Trailer

- Tank Truck

- Truck Accessories Parts

- All Wheel Drive off road truck

- Beiben truck Customizing

- Body parts

- Concrete mixer trucks

- Crane truck

- Environmental Trucks

- Fire Trucks

- ISUZU UD HINO Truck Customizing

- IVECO FOTON-FAW JAC Customizing

- Portable Tank Container

- Recovery Trucks Wrecker

- Road tanker

- SHACMAN Truck Customizing

- Special Car

- storage tank

- Machinery

- PPE

Wechat: +8615271357675

MOB: 86-152-71357675

ADD: NO.1 TAIZONG AVENUE GAOQIAO INDUSTRY PARK TAIWANESE INVESTMENT AREA DONGXIHU DISTRICT WUHAN CITY, HUBEI PROVINCE, P.R CHINA

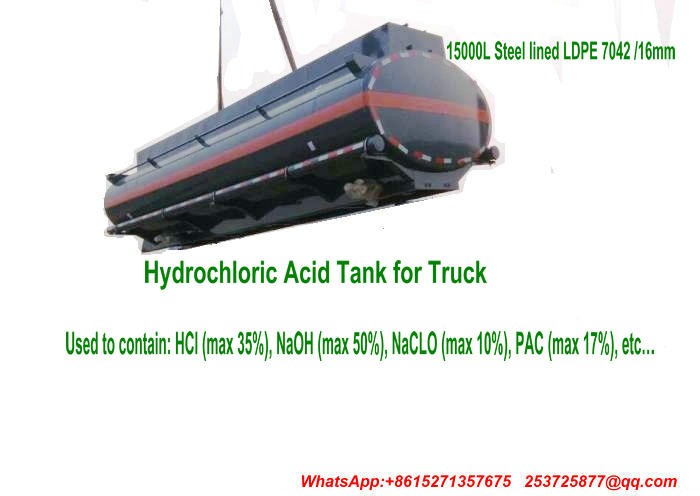

Hydrochloric Acid Tank Parts Tank Body for Truck Transport HCl (max 35%), NaOH (max 50%), NaCLO (max 10%), PAC (max 17%)

Tank Capacity: 5000L-27,000 Liters

Steel sheet 6mm, head 6mm

Liner thickness: 16mm PE

| FOB: | |

|---|---|

| Availability: | |

| Quantity: | |

|

| |

-

DR

-

DRZ

-

8707909000

Hydrochloric Acid Tank Parts Tank Body for Truck Transport HCl (max 35%), NaOH (max 50%), NaCLO (max 10%), PAC (max 17%)

Tank Capacity: 5000L-27,000 Liters

Steel sheet 6mm, head 6mm

Liner thickness: 16mm PE

Acid tank Truck upper tank body steel lined LDPE /plastic lining factory...

Hydrochloric Acid Tank Parts Tank Body for Truck Transport HCl (max 35%), NaOH (max 50%), NaCLO (max 10%), PAC (max 17%)

Tank Capacity: 5000L-27,000 Liters

Steel sheet 6mm, head 6mm

Liner thickness: 16mm PE

Acid tank Truck upper tank body steel lined LDPE /plastic lining factory...

Acid tank truck body 3~36m3 truck body Customization, Cost Control Built How You Want it, at a Price You Can Afford. for sale call:+86-152 -7135-7675 We make the Acid tank Truck Parts

Acid tank truck body truck body from 3 to 36 CBM capacity, we can make with the capacity as your request. Good design for long using life.

specializes in the manufacture of the following truck bodies:

Tipper Bodies

Water Tankers

Vacuum/Sewage Tankers (Honeysuckers)

Diesel Bowzer Tanker

Dropside Bodies

Flatdeck Bodies

Other specialized bodies on request

Chemical liquid tank

steel lined PE 16mm -18mm LDPE

Shell 5mm, 6mm

Tank net Capacity: 15000L ~18000L

3 compartment

Acid tank body steel lined PE plastic lining manhole and covers ,optional full Plastic covers!

Service/Fluid : HCl acid 32%/ Caustic Soda NaOH 32%/ Sodium

Volume : 16000

Dimension :

- Length : 5200 -6000 mm

- Width : 2300 -2500 mm

- Height : 1400 - 2300 mm

Material :steel cover + lining PE

Type : Ref. to attached drawing

Structure : with two seperated chambers

Other : (Manhole, Discharge Valve, Pressure Relief Vent, ...) type,

Hypochlorite NaClO 12%/ Ferrous chloride 40%

spec., quantity ... follow Manuf. Design, suitable for storing

and transporting of chemicals.

Acid tank Truck upper tank body steel lined PE /plastic lining shipping by containers

Acid tank Truck upper tank body steel lined PE /plastic lining shipping by Bulk ship .

Acid tank Truck upper tank body steel lined PE /plastic lining shipping by truck chassis to China border

Customize Truck

| Cell: 0086 152 7 135 7635 ; 0086 152 7 135 7675 WhatsApp: 8615271357675 tictrucks#gmail.com |  |

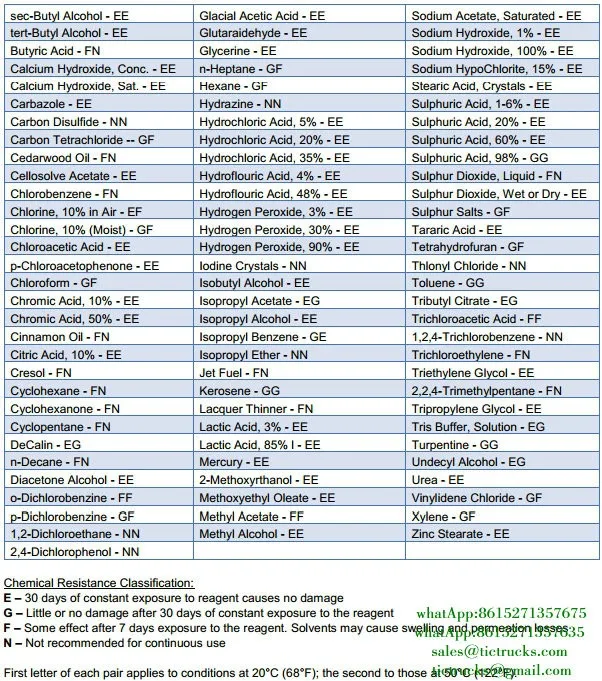

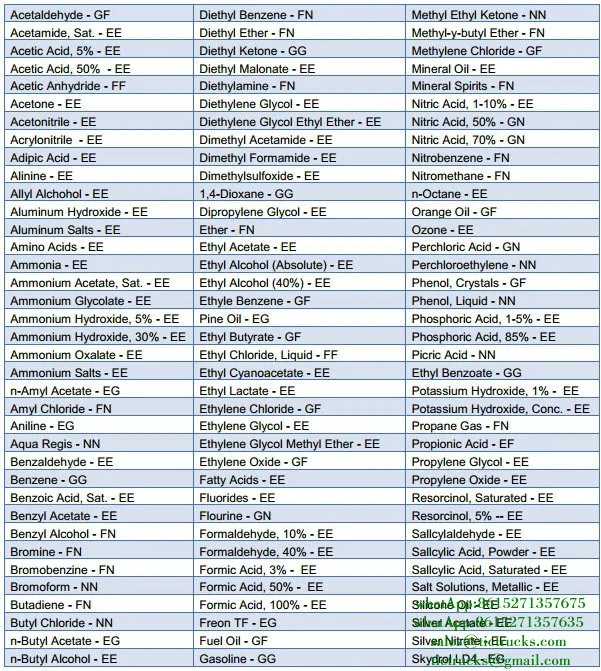

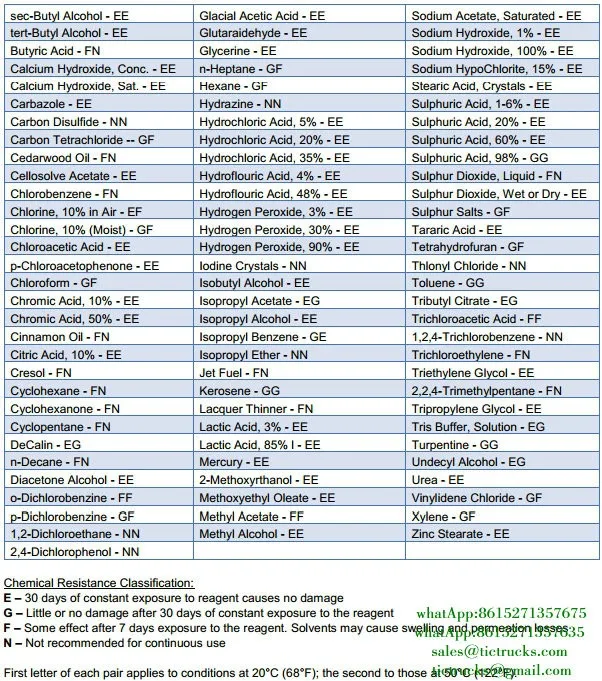

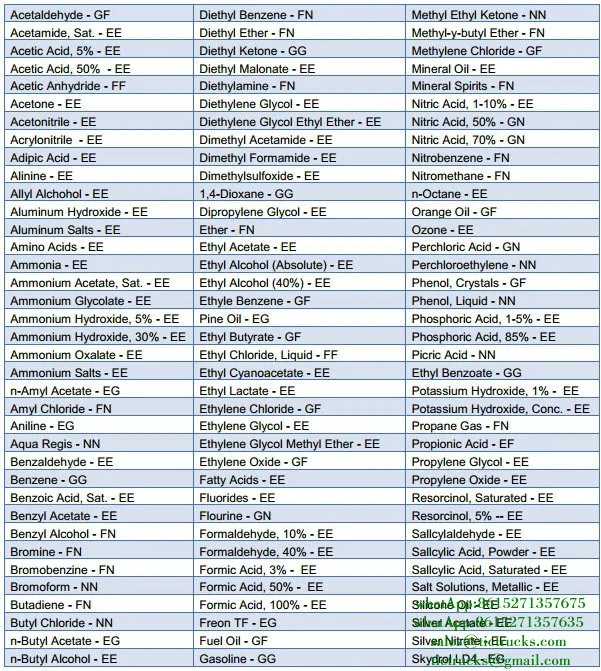

The corrosion resistance of polyethylene (PE)

Chemical Resistance Chart for LDPE (Low Density Polyethylene)

The chemical resistance chart below is a general guide only. Please contact us for specific applications

LDPE & HDPE polyethylene resistance listed by chemical

1.4-dioxane LDPE and HDPE at 20C° show little or no damage after 30 days of constant exposure. LDPE at 50C° shows

some effect after 7 days of constant exposure.

Acetaldehyde LDPE and HDPE at 20C° show little or no damage after 30 days of constant exposure. HDPE at 50C° shows

some effect after 7 days of constant exposure. LDPE - immediate damage may occur.

Acetic Acid 5 % LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Acetic Acid, glacial 50% LDPE and HDPE at 20C° show little or no damage after 30 days of constant exposure. LDPE at 50 C° -

immediate damage may occur.

Acetone LDPE and HDPE at 20C°-50C° - damage may occur. Not recommended for continuous use.

Allyl Alcohol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Aluminum salts LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Amino acids LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ammonia LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ammonium carbonate,

saturated LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ammonium phosphate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ammonium sulphate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Amyl chloride HDPE at 20C° shows some effect after 7 days of constant exposure. HDPE at 50C° and LDPE at 20C°-50C° -

immediate damage may occur. Not recommended for continuous use.

Aniline LDPE and HDPE at 20C° show little or no damage after 30 days of constant exposure. HDPE at 50C° shows

some effect after 7 days of constant exposure.

Benzene LDPE and HDPE at 20C°-50C° - damage may occur. Not recommended for continuous use.

Benzyl alcohol LDPE and HDPE at 50C° - immediate damage may occur. HDPE at 20C° shows some effect after 7 days of

constant exposure.

Boric acid LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Bromine LDPE and HDPE at 50C° - immediate damage may occur. HDPE at 20C° shows some effect after 7 days of

constant exposure.

Butyric acid LDPE and HDPE at 50C° - immediate damage may occur. HDPE at 20C° shows some effect after 7 days of

constant exposure.

Calcium chloride LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Calcium hydroxide

saturated LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Calcium sulphate No data is available at this time.

Carbon tetrachloride HDPE at 20C° shows little or no damage after 30 days. LDPE at 20C° and HDPE at 50C° show some effect

after 7 days of constant exposure. LDPE at 50C° not recommended.

Chlorobenzene Immediate damage may occur. Not recommended for continuous use.

Chloroform HDPE and LDPE at 20C° show some effect after 7 days. At -50C° - immediate damage may occur. Not

recommended for continuous use.

Chlorine 10% in water HDPE and LDPE at 20C° shows little or no damage after 30 days. LDPE at 50C° shows damage and is not

recommended.

Chromic acid 10% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Chromic acid 50% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Citric acid 10% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Cresol HDPE at 20C° shows some effect after 7 days. LDPE at 20C°-50C° and HDPE at 50C° show immediate

damage and are not recommended for continuous use.

Cyclohexane LDPE and HDPE at 50C° - immediate damage may occur. HDPE and LDPE at 20C° show some effect after 7

days of constant exposure.

Diethyl ketone LDPE and HDPE at 20C°-50C° - damage may occur. Not recommended for continuous use.

Dimethylsulfoxide LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ethanol 95% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure. Ethyl acetate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ethyl benzene HDPE at 20C° shows some effect after 7 days. LDPE at 20C°-50C° and HDPE at 50C° show immediate

damage and are not recommended for continuous use.

Ethylene glycol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ethylene oxide HDPE at 20C° shows little or no damage after 30 days of constant exposure. LDPE at 20C° and LDPE/ HDPE

at 50C° show some effect after 7 days.

Ferric chloride LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Fluoride LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Fluorine HDPE at 20C° shows little or no damage after 30 days of constant exposure. LDPE at 20C° shows some effect

after 7 days. Neither HDPE or LDPE are recommended at 50C°.

Formaldehyde 10% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Formaldehyde 40% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Glycerol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Heating oil No further data is available at this time.

Hexane HDPE at 20C° shows little or no damage after 30 days continuous use and at 50 C° shows some effect after 7

days. LDPE not recommended at any temperature.

Hydrochloric acid 5% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrochloric acid 20% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrochloric acid 35% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrocyanic acid LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrofluoric acid LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrofluoric acid 4% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrofluoric acid 48% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrogen peroxide 3% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrogen peroxide 30% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Isobutyl alcohol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Isopropyl acetate No data is available at this time.

Isopropyl alcohol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Kerosene LDPE and HDPE at 20C° show some effect after 7 days. HDPE and LDPE not recommended at 50C°, as

immediate damage may occur.

Lactic Acid 10 % LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Lactic Acid 90 % LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Lead acetate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Metallic salts, dissolved No data is available at this time.

Methanoic acid 100% No data is available at this time.

Methanol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Methyl ethyl ketone Immediate damage may occur. Not recommended for continuous use.

Methyl propyl ketone HDPE at 20C° shows some effect after 7 days. LDPE at 20C°-50C° and HDPE at 50C° - Immediate damage

may occur. Not recommended for continuous use.

Methylene chloride HDPE at 20C° shows some effect after 7 days. LDPE at 20C°-50C° and HDPE at 50C° - Immediate damage

may occur. Not recommended for continuous use.

Mineral oil LDPE and HDPE at 20C° show little or no damage after 30 days of constant exposure. LDPE at 50C° may

show immediate damage and is not recommended.

n-amyl acetate LDPE and HDPE at 20C° show little or no damage after 30 days of constant exposure. LDPE at 50C° shows

some effect after 7 days or constant exposure.

n-butyl alcohol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

n-octane LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Nitric acid 50 % LDPE at 20C° shows little or damage after 30 days. HDPE at 20C° and LDPE at 50C° show effect after 7 days.

HDPE at 50C° shows immediate damage and is not recommended.

Nitric acid 70 % HDPE and LDPE at 20C° show some effect after 7 days. Both at 50C° show immediate damage and are not

recommended.

Oleic acid HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure. LDPE at 20C°-50C° shows

immediate damage and is not recommended.

Oxalic acid LDPE at 20C° shows some effect after 7 days. HDPE at 20C° and both HDPE and LDPE at 50C° show little or

no damage after 30 days.

Ozone HDPE and LDPE at 20C° show little or no damage after 30 days of constant exposure. HDPE and LDPE at

50C° show immediate damage and are not recommended.

Perchloric acid HDPE and LDPE at 20C° show little or no damage after 30 days of constant exposure. HDPE and LDPE at 50C° show immediate damage and are not recommended.

Perchloric ethylene HDPE and LDPE at 20C°-50C° show immediate damage and are not recommended.

Phenol HDPE and LDPE at 20C°-50C° show immediate damage and are not recommended.

Phosphoric acid 10% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Phosphoric acid 85% HDPE and LDPE at 20C° show little or no damage after 30 days of constant exposure. LDPE at 50C° shows

immediate damage and is not recommended.

Phosphorous trichloride HDPE and LDPE at 20C° show little or no damage after 30 days of constant exposure. LDPE at 50C° has no

data available. HDPE at 50C° shows some effect after 7 days.

Potassium acetate No data is available at this time.

Potassium bromide No data is available at this time.

Potassium carbonate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Potassium hydroxide 5 % LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Potassium hydroxide

concentrated LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Potassium permanganate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Propylene glycol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Pyridine Immediate damage may occur. Not recommended for continuous use.

Salicylic acid, saturated LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Silver acetate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Silver nitrate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sodium carbonate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sodium chloride,

saturated LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sodium dichromate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sodium hydroxide 1% LDPE at 20C°-50C° shows little or no damage after 30 days of constant exposure. HDPE at 20C°-50C° shows

some effect after 7 days.

Sodium hydroxide 50% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sodium hypochlorite 15% HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure. LDPE at 20C° is suitable but

at 50C° shows some effect after 7 days.

Sodium nitrate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sodium sulphate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sucrose LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sulphide No additional information is available at this time.

Sulfuric acid 6% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sulfuric acid 20% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sulfuric acid 60% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sulfuric acid 98% LDPE at 20C°-50C° shows little or no damage after 30 days of constant exposure. HDPE at 20C° shoes effect

after 7 days and is not recommended for use at 50C°.

Tannic acid LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Tetrahydrofuran HDPE and LDPE at 20C° show some effect after 7 day of constant exposure.HDPE and LDPE at 50C° show

immediate damage and are not recommended.

Toluene LDPE at 20C° show some effect after 7 day of constant exposure. HDPE at 20C°-50C° and LDPE at 50C°

show immediate damage and are not recommended.

Trichloracetic acid HDPE and LDPE at 20C° show some effect after 7 day of constant exposure.HDPE and LDPE at 50C° show

immediate damage and are not recommended.

Trichlorethane Immediate damage may occur. Not recommended for continuous use.

Turpentine oil HDPE and LDPE at 20C° show some effect after 7 day of constant exposure. HDPE and LDPE at 50C° show

immediate damage and are not recommended.

Urea LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Xylene HDPE at 20C° shows some effect after 7 day of constant exposure. LDPE at 20-50C° and HDPE at 50C° show

immediate damage and are not recommended.

Zinc chloride LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Acid tank truck body 3~36m3 truck body Customization, Cost Control Built How You Want it, at a Price You Can Afford. for sale call:+86-152 -7135-7675 We make the Acid tank Truck Parts

Acid tank truck body truck body from 3 to 36 CBM capacity, we can make with the capacity as your request. Good design for long using life.

specializes in the manufacture of the following truck bodies:

Tipper Bodies

Water Tankers

Vacuum/Sewage Tankers (Honeysuckers)

Diesel Bowzer Tanker

Dropside Bodies

Flatdeck Bodies

Other specialized bodies on request

Chemical liquid tank

steel lined PE 16mm -18mm LDPE

Shell 5mm, 6mm

Tank net Capacity: 15000L ~18000L

3 compartment

Acid tank body steel lined PE plastic lining manhole and covers ,optional full Plastic covers!

Service/Fluid : HCl acid 32%/ Caustic Soda NaOH 32%/ Sodium

Volume : 16000

Dimension :

- Length : 5200 -6000 mm

- Width : 2300 -2500 mm

- Height : 1400 - 2300 mm

Material :steel cover + lining PE

Type : Ref. to attached drawing

Structure : with two seperated chambers

Other : (Manhole, Discharge Valve, Pressure Relief Vent, ...) type,

Hypochlorite NaClO 12%/ Ferrous chloride 40%

spec., quantity ... follow Manuf. Design, suitable for storing

and transporting of chemicals.

Acid tank Truck upper tank body steel lined PE /plastic lining shipping by containers

Acid tank Truck upper tank body steel lined PE /plastic lining shipping by Bulk ship .

Acid tank Truck upper tank body steel lined PE /plastic lining shipping by truck chassis to China border

Customize Truck

| Cell: 0086 152 7 135 7635 ; 0086 152 7 135 7675 WhatsApp: 8615271357675 tictrucks#gmail.com |  |

The corrosion resistance of polyethylene (PE)

Chemical Resistance Chart for LDPE (Low Density Polyethylene)

The chemical resistance chart below is a general guide only. Please contact us for specific applications

LDPE & HDPE polyethylene resistance listed by chemical

1.4-dioxane LDPE and HDPE at 20C° show little or no damage after 30 days of constant exposure. LDPE at 50C° shows

some effect after 7 days of constant exposure.

Acetaldehyde LDPE and HDPE at 20C° show little or no damage after 30 days of constant exposure. HDPE at 50C° shows

some effect after 7 days of constant exposure. LDPE - immediate damage may occur.

Acetic Acid 5 % LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Acetic Acid, glacial 50% LDPE and HDPE at 20C° show little or no damage after 30 days of constant exposure. LDPE at 50 C° -

immediate damage may occur.

Acetone LDPE and HDPE at 20C°-50C° - damage may occur. Not recommended for continuous use.

Allyl Alcohol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Aluminum salts LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Amino acids LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ammonia LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ammonium carbonate,

saturated LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ammonium phosphate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ammonium sulphate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Amyl chloride HDPE at 20C° shows some effect after 7 days of constant exposure. HDPE at 50C° and LDPE at 20C°-50C° -

immediate damage may occur. Not recommended for continuous use.

Aniline LDPE and HDPE at 20C° show little or no damage after 30 days of constant exposure. HDPE at 50C° shows

some effect after 7 days of constant exposure.

Benzene LDPE and HDPE at 20C°-50C° - damage may occur. Not recommended for continuous use.

Benzyl alcohol LDPE and HDPE at 50C° - immediate damage may occur. HDPE at 20C° shows some effect after 7 days of

constant exposure.

Boric acid LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Bromine LDPE and HDPE at 50C° - immediate damage may occur. HDPE at 20C° shows some effect after 7 days of

constant exposure.

Butyric acid LDPE and HDPE at 50C° - immediate damage may occur. HDPE at 20C° shows some effect after 7 days of

constant exposure.

Calcium chloride LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Calcium hydroxide

saturated LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Calcium sulphate No data is available at this time.

Carbon tetrachloride HDPE at 20C° shows little or no damage after 30 days. LDPE at 20C° and HDPE at 50C° show some effect

after 7 days of constant exposure. LDPE at 50C° not recommended.

Chlorobenzene Immediate damage may occur. Not recommended for continuous use.

Chloroform HDPE and LDPE at 20C° show some effect after 7 days. At -50C° - immediate damage may occur. Not

recommended for continuous use.

Chlorine 10% in water HDPE and LDPE at 20C° shows little or no damage after 30 days. LDPE at 50C° shows damage and is not

recommended.

Chromic acid 10% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Chromic acid 50% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Citric acid 10% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Cresol HDPE at 20C° shows some effect after 7 days. LDPE at 20C°-50C° and HDPE at 50C° show immediate

damage and are not recommended for continuous use.

Cyclohexane LDPE and HDPE at 50C° - immediate damage may occur. HDPE and LDPE at 20C° show some effect after 7

days of constant exposure.

Diethyl ketone LDPE and HDPE at 20C°-50C° - damage may occur. Not recommended for continuous use.

Dimethylsulfoxide LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ethanol 95% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure. Ethyl acetate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ethyl benzene HDPE at 20C° shows some effect after 7 days. LDPE at 20C°-50C° and HDPE at 50C° show immediate

damage and are not recommended for continuous use.

Ethylene glycol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Ethylene oxide HDPE at 20C° shows little or no damage after 30 days of constant exposure. LDPE at 20C° and LDPE/ HDPE

at 50C° show some effect after 7 days.

Ferric chloride LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Fluoride LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Fluorine HDPE at 20C° shows little or no damage after 30 days of constant exposure. LDPE at 20C° shows some effect

after 7 days. Neither HDPE or LDPE are recommended at 50C°.

Formaldehyde 10% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Formaldehyde 40% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Glycerol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Heating oil No further data is available at this time.

Hexane HDPE at 20C° shows little or no damage after 30 days continuous use and at 50 C° shows some effect after 7

days. LDPE not recommended at any temperature.

Hydrochloric acid 5% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrochloric acid 20% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrochloric acid 35% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrocyanic acid LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrofluoric acid LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrofluoric acid 4% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrofluoric acid 48% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrogen peroxide 3% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Hydrogen peroxide 30% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Isobutyl alcohol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Isopropyl acetate No data is available at this time.

Isopropyl alcohol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Kerosene LDPE and HDPE at 20C° show some effect after 7 days. HDPE and LDPE not recommended at 50C°, as

immediate damage may occur.

Lactic Acid 10 % LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Lactic Acid 90 % LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Lead acetate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Metallic salts, dissolved No data is available at this time.

Methanoic acid 100% No data is available at this time.

Methanol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Methyl ethyl ketone Immediate damage may occur. Not recommended for continuous use.

Methyl propyl ketone HDPE at 20C° shows some effect after 7 days. LDPE at 20C°-50C° and HDPE at 50C° - Immediate damage

may occur. Not recommended for continuous use.

Methylene chloride HDPE at 20C° shows some effect after 7 days. LDPE at 20C°-50C° and HDPE at 50C° - Immediate damage

may occur. Not recommended for continuous use.

Mineral oil LDPE and HDPE at 20C° show little or no damage after 30 days of constant exposure. LDPE at 50C° may

show immediate damage and is not recommended.

n-amyl acetate LDPE and HDPE at 20C° show little or no damage after 30 days of constant exposure. LDPE at 50C° shows

some effect after 7 days or constant exposure.

n-butyl alcohol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

n-octane LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Nitric acid 50 % LDPE at 20C° shows little or damage after 30 days. HDPE at 20C° and LDPE at 50C° show effect after 7 days.

HDPE at 50C° shows immediate damage and is not recommended.

Nitric acid 70 % HDPE and LDPE at 20C° show some effect after 7 days. Both at 50C° show immediate damage and are not

recommended.

Oleic acid HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure. LDPE at 20C°-50C° shows

immediate damage and is not recommended.

Oxalic acid LDPE at 20C° shows some effect after 7 days. HDPE at 20C° and both HDPE and LDPE at 50C° show little or

no damage after 30 days.

Ozone HDPE and LDPE at 20C° show little or no damage after 30 days of constant exposure. HDPE and LDPE at

50C° show immediate damage and are not recommended.

Perchloric acid HDPE and LDPE at 20C° show little or no damage after 30 days of constant exposure. HDPE and LDPE at 50C° show immediate damage and are not recommended.

Perchloric ethylene HDPE and LDPE at 20C°-50C° show immediate damage and are not recommended.

Phenol HDPE and LDPE at 20C°-50C° show immediate damage and are not recommended.

Phosphoric acid 10% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Phosphoric acid 85% HDPE and LDPE at 20C° show little or no damage after 30 days of constant exposure. LDPE at 50C° shows

immediate damage and is not recommended.

Phosphorous trichloride HDPE and LDPE at 20C° show little or no damage after 30 days of constant exposure. LDPE at 50C° has no

data available. HDPE at 50C° shows some effect after 7 days.

Potassium acetate No data is available at this time.

Potassium bromide No data is available at this time.

Potassium carbonate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Potassium hydroxide 5 % LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Potassium hydroxide

concentrated LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Potassium permanganate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Propylene glycol LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Pyridine Immediate damage may occur. Not recommended for continuous use.

Salicylic acid, saturated LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Silver acetate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Silver nitrate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sodium carbonate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sodium chloride,

saturated LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sodium dichromate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sodium hydroxide 1% LDPE at 20C°-50C° shows little or no damage after 30 days of constant exposure. HDPE at 20C°-50C° shows

some effect after 7 days.

Sodium hydroxide 50% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sodium hypochlorite 15% HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure. LDPE at 20C° is suitable but

at 50C° shows some effect after 7 days.

Sodium nitrate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sodium sulphate LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sucrose LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sulphide No additional information is available at this time.

Sulfuric acid 6% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sulfuric acid 20% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sulfuric acid 60% LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Sulfuric acid 98% LDPE at 20C°-50C° shows little or no damage after 30 days of constant exposure. HDPE at 20C° shoes effect

after 7 days and is not recommended for use at 50C°.

Tannic acid LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Tetrahydrofuran HDPE and LDPE at 20C° show some effect after 7 day of constant exposure.HDPE and LDPE at 50C° show

immediate damage and are not recommended.

Toluene LDPE at 20C° show some effect after 7 day of constant exposure. HDPE at 20C°-50C° and LDPE at 50C°

show immediate damage and are not recommended.

Trichloracetic acid HDPE and LDPE at 20C° show some effect after 7 day of constant exposure.HDPE and LDPE at 50C° show

immediate damage and are not recommended.

Trichlorethane Immediate damage may occur. Not recommended for continuous use.

Turpentine oil HDPE and LDPE at 20C° show some effect after 7 day of constant exposure. HDPE and LDPE at 50C° show

immediate damage and are not recommended.

Urea LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Xylene HDPE at 20C° shows some effect after 7 day of constant exposure. LDPE at 20-50C° and HDPE at 50C° show

immediate damage and are not recommended.

Zinc chloride LDPE and HDPE at 20C°-50C° show little or no damage after 30 days of constant exposure.

Related Products

SUCCESS CASES

More >>- 2025-11-11T7 T14 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India

T7 T14 PE Lined ISO Tank Container for Hydrogen Peroxide (H₂O₂) HCL,KOH Potassium Hydroxide for India DHF, HCL,KOH , H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide 20FT TANK CONTAINER (EMPTY AND NEW TANKS) DTAU2509090 DTAU2509103 LOADING MEDIUM :POTASSIUM HYDROXIDE 49% UN1814 KOH HYDROGEN PEROXIDE 50% UN2014 H2O2 HYDROCHLORIC ACID 36% UN1789 HCL , UN1830 H2SO4 DILUTED SULFURIC ACID 1%~ 50%~ 94%, UN2031 HNO3 NITRIC ACID 1%~30%~50%, NaOH 50% CAUSTIC SODA AND OTHER CHEMICALS

- 2025-09-28Advantages And Disadvantages of Different Material Storage T8 T14 PE / PTFE Lined ISO Tank Container for Electronic Grade Hydrogen Peroxide (H₂O₂) HCL,KOH

Advantages And Disadvantages of Different Material Storage T8 T14 PE / PTFE Lined ISO Tank Container for Electronic Grade Hydrogen Peroxide (H₂O₂) DTAU2509016 DTAU2509021 DTAU2509037

- 2025-09-016PCS T7 T14 PE Lined ISO Tank Container for HCL, PAC Hydrochloric Acid / Chemical Poly Aluminum Chloride 21KL To Vietnam

6PCS T7 T14 PE Lined ISO Tank Container for HCL, PAC Hydrochloric Acid / Chemical Poly Aluminum Chloride 21KL To Vietnam road transport type PE Lined Tank Used to contain: HCl , NaOH , PAC , H2SO4(max 98%) etc. Tank Capacity: 21,000 Liters 21m3 Steel sheet 6mm, head 6mm Liner thickness: 16mm PE 20 FT TANK (EMPTY AND NEW TANKS) HCDA2505016 HCDA2505021 HCDA2505037 HCDA2505042 HCDA2505058 HCDA2505063

- 2025-08-293 Units PE Lined T7 T8 T14 ISO Tank Container for DHF,HCL,KOH,H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide Export To India

3 Units PE Lined T7 T8 T14 ISO Tank Container for DHF,HCL,KOH,H2O2 Hydrofluoric Acid/ Hydrochloric Acid/ Potassium Hydroxide / Hydrogen Peroxide Export To India DTAU2508010 DTAU2508025 DTAU2508030 20FT TANK CONTAINER (EMPTY AND NEW TANKS)

- 2025-06-1820PCS UN 3394 3399 Portable Tanks C-480 TMA Cylinders to USA

20PCS UN 3394 3399 Portable Tanks C-480 TMA Cylinders to USA PORTABLE TANK (EMPTY AND NEW TANKS) C-480 CYLINDER HS:860900.00(USA) Adr/Rid Organometallic Substance, Liquid, Water- Reactive C-480 Saddle Type Portable Tank, tank capacity 1880L KS1880-T21 Portable Tanks ASME Test DATA Report(C250051-C250070) BV Certificate No.:IIC-BVCT2570036S KSVU 250051 -70 Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg

- 2025-04-034 Units T14 ISO Tank Container PE Lined for Hydrofluoric HF Hydrochloric Acid HCL, Ferric Chloride Potassium Hydroxide KOH Tank Container Export To India

4 Units T14 ISO Tank Container PE Lined for Hydrofluoric HF Hydrochloric Acid HCL, Ferric Chloride Potassium Hydroxide KOH Tank Container Export To India DTAU2502011 DTAU2502027 DTAU2502032 DTAU2502048 20 FT TANK CONTAINER FOR HYDROCHLORIC ACID UN1789 HCL, HYDROFLUORIC ACID UN1790 HF ACID CARON STEEL AND LINED WITH 16MM LLDPE TANKS CAPACITY 21 KL FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, TOP UNLOADING TARE WEIGHT 5200KG 1UNIT 20FT TANK CONTAINER FOR UN1814 KOH POTASSIUM HYDROXIDE 45% SOLUTION DISH HEAD TYPE TANK CAPACITY: 19000LITERS FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, BOTTOM UNLOADING TARE WEIGHT 5300KG 1UNIT 20FT TANK CONTAINER FOR UN2014 H2O2 HYDROGEN PEROXIDE 31% SOLUTION DISH HEAD TYPE TANK CAPACITY: 19000LITERS FOR ROAD INLAND MOVEMENTS SHELL THICKNESS 6MM ,HEAD 8MM LLDPE 16MM, BOTTOM UNLOADING TARE WEIGHT 5300KG 2UNITS

- 2025-04-01Steel Lined PE Plastic ISO Tank for Hydrochloric Acid HCL12KL,15KL/16KL/19KL/22KL To Vietnam

Steel Lined PE Plastic ISO Tank for Hydrochloric Acid HCL12KL,15KL/16KL/19KL/22KL To Vietnam Description of goods Quantity N.W PE LINED STEEL TANK 5100X 2350 X 1400MM / 12.5M3 (EMPTY AND NEW TANKS) MODEL: DTA5212 HS CODE : 7309000000 、6300KGS PE LINED STEEL TANK 6040 X 2400 X 1600MM / 15.8M3 (EMPTY AND NEW TANKS) MODEL: DTA5215 HS CODE : 7309000000 1 3650KG PE LINED STEEL TANK 7190 X 2300X 1300MM / 16.2M3 (EMPTY AND NEW TANKS) MODEL: DTA5316 HS CODE : 7309000000 、4350KG PE LINED STEEL TANK 8520 X 2260 X 1350MM / 19.5M3 (EMPTY AND NEW TANKS) MODEL: DTA5319 HS CODE : 7309000000 、4850KG 20 FT TANK CONTAINER 6058X2438X2591MM / 22.8M3 (EMPTY AND NEW TANKS) MODEL: DTAU2501015 、5800KG

- 2025-02-261000L SS304 Stainless Steel Lined PE Plastic Tank for Hydrochloric Acid to GUAYAQUIL, EC

1000L SS304 Stainless Steel Lined PE Plastic Tank for Hydrochloric Acid to GUAYAQUIL, EC STORAGE TANK 304 STAINLESS STEEL LINED PLASTIC TANK VERTICAL TANK STAINLESS STEEL 304 THICKNESS 5MM+PE 16MM CAPACITY: 1,000 L RESIST 15%~38% HYDROCHLORIC ACID HS CODE:730900

- 2025-01-1920PCS Metal Alky TEAL C480 T21 UN Portable Tank Cylinders To USA

20Units UN T21 Portable Tank Container 1880L Cylinder For TEAL Metal Alkyls UN3394 UN3399 to USA with 30pcs Spare PSV RELIEF VALVES SF/A412F-25P(3B) Manufacturer (SHENYANG XINGUANG VALVE ) KS1880-T21 Portable Tanks Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg KSVU240016 -KSVU240035 Adr/Rid Organometallic Substance, Liquid, Water- Reactive C-480 Saddle Type Portable Tank, tank capacity 1880L

- 2024-12-206 Sets Thermal Insulated LLDPE Lined Tanks 25KL for Sodium Hypochlorite Hydrochloric Acid Storage Transport Tanker To Saudi Arabia

6 Sets Thermal Insulated LLDPE Lined Tanks 25KL for Sodium Hypochlorite Hydrochloric Acid To Saudi Arabia Lined PE Tanks 6604Gallon For Truck Trailer mounted FROM WUHAN PORT CHINA TO DAMMAM, SAUDI ARABIA BY SEA. + Port of loading : WUHAN PORT + Port of unloading :DAMMAM SAUDI ARABIA

- 2024-12-022 Units T14 Hydrofluoric Hydrochloric Acid UN1789 UN1790 ISOTank Container Road Transport For ASCOR

2 Units T14 Hydrofluoric Hydrochloric Acid UN1789 UN1790 ISOTank Container Road Transport For ASCOR 20FT Tank Container (EMPTY AND NEW TANKS) FOR HYDROCHLORIC ACID UN1789 HCL HYDROFLUORIC ACID HF ACID UN1790 CARBON STEEL AND LINED WITH 16MM LLDPE DTAU2404015, DTAU2404020

- 2024-10-245 Units C480 Keystone Vessel T21 TEAL Cylinder UN Portable Tanks To SAUDI ARABIA

5 Units Keystone Vessel T21 TEAL UN Portable Tank C480 Cylinder To SAUDI ARABIA KS1880-T21 Portable Tanks Max. gross mass : 4000 kg Tare : 1050 kg Payload : 2950 kg KSVU2400114 KSVU2400120 KSVU2400135 KSVU2400140 KSVU2400156

- 2024-09-247 Units T14 Hydrofluoric Acid ISO Tank Container For Export to India

7 Units T14 Hydrofluoric Acid ISO Tank Container For Export to India 20FT TANK CONTAINER (EMPTY AND NEW TANKS) 20 FT TANK CONTAINER FOR HYDROFLUORIC ACID UN1790 HF ACID, CARON STEEL AND LINED WITH 16 MM LLDPE TANKS CAPACITY 21 KL COUNTRY OF ORIGIN : CHINA MARKING TANK NO.: DTAU2407014 DTAU2407020 DTAU2407035 DTAU2407040 DTAU2407056 DTAU2407061 DTAU2407077

- 2024-08-202 UNITS 20FT Sodium Cyanide ISO Tank Container for West Africa Global Mine Operations

2 UNITS 20FT Sodium Cyanide ISO Tank Container for West Africa Global Mine Operations 20FT Tank Container for Sodium Cyanide carbon steel and lined with 16mm LLDPE Specialized Tank Container, Sodium Cyanide Tank T6, Capacity 20000litre Hydrochloric acid with the concentration of 1789 (38%) 2X20TK DTAU2024611 DTAU2024627

- 2024-08-14PE Lined 20FT ISOTank Container For HCL Acid KOH 18KL To Vietnam

PE Lined 20FT ISOTank Container For HCL Acid KOH 18KL To Vietnam (EMPTY AND NEW TANKS) TANK CAPACITY: 18M3 DTAU2407082