Equipment For Sale

- Aerial platform truck

- Dolly Trailer

- ISO Tank

- Recovery Trucks

- Road Sweeper

- SKD Truck Body

- Special Vehicle

- Tank Trailer

- Tank Truck

- Truck Accessories Parts

- All Wheel Drive off road truck

- Body parts

- Concrete mixer trucks

- Crane truck

- Environmental Trucks

- Fire Trucks

- Portable Tank Container

- Recovery Trucks Wrecker

- Road tanker

- Special Car

- storage tank

- Machinery

- PPE

Wechat: +8615271357675

MOB: 86-152-71357675

ADD: NO.1 TAIZONG AVENUE GAOQIAO INDUSTRY PARK TAIWANESE INVESTMENT AREA DONGXIHU DISTRICT WUHAN CITY, HUBEI PROVINCE, P.R CHINA

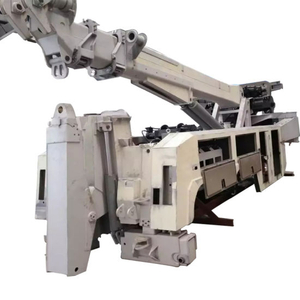

Asphalt Tank SKD for Asphalt Spray Truck (Asphalt Distributor Truck Body Part 4000L, 6000L, 8000L, 10000L Bitumen Distributor Tank)

| Availability: | |

|---|---|

| Quantity: | |

-

Shanghai, China

-

3000

-

T/T

Asphalt Tank SKD for Asphalt Spray Truck (Asphalt Distributor Truck Body Part 4000L,6000L ,8000L ,10000L Bitumen Distributor Tank)

Cell /+8615271357675

The pictures are for your reference only. Bitumen Sprayer

| 5110GLQ5 | |||

| Product name: | Bitumen Distributor | Dimensions (mm): | 7180x2250x2650 |

| Chassis model: | EQ1110SJ8BDC | Tank capacity : | 5.6m3 |

| Total quality : (kg) | 11450 | Approach/departure angle | 21/14 |

| Rated quality: (kg) | 4805 | Front overhang / rear overhang (mm): | 1130/2250,1150/2230 |

| Curb weight: (kg) | 6450 | Maximum speed (km/h): | 103 |

| Axle load: | 4360/7090 | ||

| Chassis | |||

| Chassis model: | EQ1110SJ8BDC | ||

| Number of axes: | 2 | Fuel type: | Diesel |

| Shaft distance (mm): | 3800 | Front wheel distance (mm): | 1745,1747,1823 |

| Rated passenger (including driver): | Rear wheel distance (mm): | 1620,1806,1800,1715 | |

| Number of tires: | 6 | Number of springs: | 8/10+7 |

| Tire specifications: | 8.25R20 14PR,245/70R19.5 | ||

| Vehicle description: | Tank effective volume :5.6 cubic meters, transport medium is liquid asphalt, density :900 kg/cubic meters. External dimensions of tank(mm):3500/1950/1380(internal dimensions of tank: 3400/1850/1280) | ||

| Engine parameters Emission standard: GB17691-2005 EURO V, GB3847-2005 | ||||

| Engine type | Engine manufacturer | Displacement (ml) | Power (kw) | |

| CY4SK251 YC4S150-50 ISF3.8s5154 4DX23-140E5 YN38CRE1 YC4Y22-15050 YNF40E1 | Dongfeng Chaoyang Chaochai Power Co., Ltd. Guangxi Yuchai Machinery Co., Ltd. Beijing Futian Cummins Engine Co., Ltd. FAW Jiefang Automobile Co., Ltd. Wuxi Diesel Engine Factory Kunming Yunnei Power Co., Ltd. Guangxi Yuchai Machinery Co., Ltd. Kunming Yunnei Power Co., Ltd. | 3856 3767 3760 3857 3760 2169 3920 | 115 110 115 105 95 110 125 | |

| Configuration Type | Details of Asphalt truck | |||

| Normal configuration Simple type | 1. Asphalt pump: ZP230 insulation type high viscosity asphalt pump; 2. Asphalt pump drive motor: GM05 series high-torque plunger motor; 3. Burner: G10 imported from Italy 4. Temperature control: AI-218 microcomputer temperature controller; 5. Spreading width: 1.2m ~ 4.5m, optional 6m 6. Spray control: manual adjustment 7. Asphalt pipeline compressed air cleaning function | |||

| Ordinary configuration | 1. Asphalt pump: ZP230 insulation type high viscosity asphalt pump; 2. Asphalt pump drive motor: GM05 series high-torque plunger motor; 3. Hydraulic pump: F563 aluminum alloy gear pump; 4. Hydraulic system: manual flow control valve imported; 5. Burner: G10 imported from Italy 6. Temperature control: AI-218 microcomputer temperature controller; 7. Spreading width: 1.2m ~ 4.5m, optional 6m 8. Sprinkler control: manually adjust asphalt pipe 9. Asphalt pipeline compressed air cleaning function | |||

| Ordinary upgrade configuration | 1. Asphalt pump: ZP230 insulation type high viscosity asphalt pump; 2. Asphalt pump drive motor: GM05 series high-torque plunger motor; 3. Hydraulic pump: F563 aluminum alloy gear pump; 4. Hydraulic system: imported proportional flow control valve; 5. Burner: G10 imported from Italy 6. Heating method: automatically heating by heat-conduction oil 7. Temperature control: AI microcomputer temperature controller; 8. Width of Spray : 1.2m ~ 4.5m, optional 6m precise triple overlapping Spray , 9. Spraying quantity control: manually adjust asphalt nozzle; 10. Asphalt pipeline compressed air cleaning function | |||

| Semi-intelligent configuration | 1. Asphalt pump: ZP230 insulation type high viscosity asphalt pump; 2. Asphalt pump drive motor: GM05 series high-torque plunger motor; 3. Hydraulic pump: F563 aluminum alloy gear pump; 4. Hydraulic system: imported proportional flow control valve; 5. Burner: G10 imported from Italy 6. Heating method: automatically heating by heat-conduction oil 7. Temperature control: AI microcomputer temperature controller; 8. Maximum width of Spray : 4.5 meters, optional 6 meters, precise three overlapping Spray , fully electric controln ozzle, 9. Sprinkler control: front and background potentiometer adjustment, digital display; 10. Asphalt pipeline compressed air cleaning function | |||

| Full intelligent configuration | 1. Asphalt pump: ZP230 insulation type high viscosity asphalt pump; 2. Asphalt pump drive motor: GM05 series high-torque plunger motor; 3. Hydraulic pump: F563 aluminum alloy gear pump; 4. Hydraulic system: imported proportional flow control valve; 5. Burner: G10 imported from Italy 6. Heating method: automatically heating by heat-conduction oil with selective heating function 7.temperature control: Germany Siemens temperature control module, computer temperature control 8. Maximum width of Spray : 4.5 meters, optional 6 meters, precise three overlapping Spray , fully electric control nozzle, 9. Sprinkling width is precisely controlled by computer: sprinkling quantity control: Germany Siemens PLC, intelligent control, sprinkling quantity and speed precise linkage, front touch screen control system. 10. Asphalt pipeline compressed air cleaning function | |||

| Full intelligent configuration imported Pump |

3. Hydraulic pump: Germany leisler plunger variable pump; 4. Hydraulic system: imported proportional flow control valve; 5. Burner: G10 imported from Italy 6. Heating method: automatically heating by heat-conduction oil with selective heating function 7.temperature control: Germany Siemens temperature control module, computer temperature control 8. Maximum width of Spray : 4.5 meters, optional 6 meters, precise three overlapping Spray , fully electric control nozzle, 9. Sprinkling width is precisely controlled by computer: sprinkling quantity control: Germany Siemens PLC, intelligent control, sprinkling quantity and speed precise linkage, front touch screen control system. 10. Asphalt pipeline compressed air cleaning function 11.spray volume 0.2 ~ 3 kg / , 28 sets of full electric nozzle, | |||

Our products enjoy a good reputation for the good quality!

The asphalt distributor is made up by chassis, asphalt tank, asphalt pump, optional conduction oil heating system, electronic control system and spraybar system, etc.

Major features:

1) Digital display meters and instruments to indicate speed of the vehicle and the asphalt pump rotation, as well as temperature of asphalt inside the tank.

2) Possesses heat preservation, conduction oil recycling heating, transportation, spray, pumping and discharge function, etc.

3) Nozzle controlled through pneumatic joint control operation of cylinder for opening and closing.

4) Cleaning system of compressed air

5) Hydraulic power take-off of chassis or auxiliary diesel engine for drive, heated with burner, optional conduction oil recycling system.

Technical Specifications:

Electronic control series

| Model | P3 | P4 | P6 | P8 | P10 | P12 | |

| Chassis | BJ1073 BJ1083 | BJ1103 BJ1120 | BJ1163 BJ5163 | SX1255 | ND1254 | ND1255 | |

| Capacity of asphalt tank (L) | 3000 | 4000 | 6000 | 8000 | 11000 | 12000 | |

| Max. distribution width(m) | 4 | 4.5 | 6 | 6 | 6 | 6 | |

| Distribution capacity (kg/m2) | 0.3-1.8 | 0.3-2.5 | 0.3-3 | 0.3-3 | 0.3-3 | 0.3-3 | |

| Distribution precision (%) | ≤2 | ||||||

| Heating mode | Diesel burner Heat capacity | ||||||

| 8×104Kcal/h | 8×104Kcal/h | 10×104Kcal/h | 15×104Kcal/h | 19×104Kcal/h | 19×104Kcal/h | ||

| Average Temp. Drop (°C/h) | ≤1 | ≤1 | ≤1 | ≤1.5 | ≤1.5 | ≤1.5 | |

Before sales:

1.Gratis professional consultant service,multi solution options, and most suitable product recommendation.

2.Special product design and manufacture based on your requirements.

3.Gratis professtional technology consultant,and detailed equipment working scheme as reference,for your special project.

After sales:

1.Gratis professional technology training,to train qualified operator for you.

2.Satisfying solution response in 2 hours after your quality feedback.

3.Equipment repair warranty(details in contract attachment),life time repair service(only free of charge of labour cost).

4.Save your individual product records.Asphalt distributor

Smart Intelligent control series

Major features:The distributor is made up by chassis, asphalt tank, asphalt pump, conduction oil

heating system, electrical and automatic control system and cleaning system, etc. with main units

made of the most up-to-date components in the international community, all-round control with

micro-computer, high distribution precision.

Three layers of overlapped cloth for spray, adjustable distribution capacity based on the

traveling speed, totally operable in the cabin for distribution

Separate control with computer at each spraybar of adjustable width.

Two control systems in the control process for the whole truck (cabin and rear operating platform) to ensure reliable and successful asphalt distribution.

All-round heating of pump, spraybar and tank with conduction oil or separate heating.

Optional radar speed measurement system

Safe and reliable conduction oil heating system for fully automatic control

| Model | S4 | S7 | S8 | S10 | S12 | |

| Chassis | BJ1103 BJ1120 | BJ5163 | SX1165 | SX1255 | ND1254 | |

| Capacity of asphalt tank (L) | 4000 | 6800 | 8000 | 10000 | 12000 | |

| Max. distribution width(m) | 4.5 | 6 | 6 | 6 | 6 | |

| Distribution capacity (kg/m2) | 0.3-2.5 | 0.3-3 | 0.3-3 | 0.3-3 | 0.3-3 | |

| Heating Mode | Diesel Burner Heat capacity | |||||

| 8×104Kcal/h | 12×104Kcal/h | 14×104Kcal/h | 19×104Kcal/h | 19×104Kcal/h | ||

Cell :+8615271357675

Asphalt Tank SKD for Asphalt Spray Truck (Asphalt Distributor Truck Body Part 4000L,6000L ,8000L ,10000L Bitumen Distributor Tank)

Cell /+8615271357675

The pictures are for your reference only. Bitumen Sprayer

| 5110GLQ5 | |||

| Product name: | Bitumen Distributor | Dimensions (mm): | 7180x2250x2650 |

| Chassis model: | EQ1110SJ8BDC | Tank capacity : | 5.6m3 |

| Total quality : (kg) | 11450 | Approach/departure angle | 21/14 |

| Rated quality: (kg) | 4805 | Front overhang / rear overhang (mm): | 1130/2250,1150/2230 |

| Curb weight: (kg) | 6450 | Maximum speed (km/h): | 103 |

| Axle load: | 4360/7090 | ||

| Chassis | |||

| Chassis model: | EQ1110SJ8BDC | ||

| Number of axes: | 2 | Fuel type: | Diesel |

| Shaft distance (mm): | 3800 | Front wheel distance (mm): | 1745,1747,1823 |

| Rated passenger (including driver): | Rear wheel distance (mm): | 1620,1806,1800,1715 | |

| Number of tires: | 6 | Number of springs: | 8/10+7 |

| Tire specifications: | 8.25R20 14PR,245/70R19.5 | ||

| Vehicle description: | Tank effective volume :5.6 cubic meters, transport medium is liquid asphalt, density :900 kg/cubic meters. External dimensions of tank(mm):3500/1950/1380(internal dimensions of tank: 3400/1850/1280) | ||

| Engine parameters Emission standard: GB17691-2005 EURO V, GB3847-2005 | ||||

| Engine type | Engine manufacturer | Displacement (ml) | Power (kw) | |

| CY4SK251 YC4S150-50 ISF3.8s5154 4DX23-140E5 YN38CRE1 YC4Y22-15050 YNF40E1 | Dongfeng Chaoyang Chaochai Power Co., Ltd. Guangxi Yuchai Machinery Co., Ltd. Beijing Futian Cummins Engine Co., Ltd. FAW Jiefang Automobile Co., Ltd. Wuxi Diesel Engine Factory Kunming Yunnei Power Co., Ltd. Guangxi Yuchai Machinery Co., Ltd. Kunming Yunnei Power Co., Ltd. | 3856 3767 3760 3857 3760 2169 3920 | 115 110 115 105 95 110 125 | |

| Configuration Type | Details of Asphalt truck | |||

| Normal configuration Simple type | 1. Asphalt pump: ZP230 insulation type high viscosity asphalt pump; 2. Asphalt pump drive motor: GM05 series high-torque plunger motor; 3. Burner: G10 imported from Italy 4. Temperature control: AI-218 microcomputer temperature controller; 5. Spreading width: 1.2m ~ 4.5m, optional 6m 6. Spray control: manual adjustment 7. Asphalt pipeline compressed air cleaning function | |||

| Ordinary configuration | 1. Asphalt pump: ZP230 insulation type high viscosity asphalt pump; 2. Asphalt pump drive motor: GM05 series high-torque plunger motor; 3. Hydraulic pump: F563 aluminum alloy gear pump; 4. Hydraulic system: manual flow control valve imported; 5. Burner: G10 imported from Italy 6. Temperature control: AI-218 microcomputer temperature controller; 7. Spreading width: 1.2m ~ 4.5m, optional 6m 8. Sprinkler control: manually adjust asphalt pipe 9. Asphalt pipeline compressed air cleaning function | |||

| Ordinary upgrade configuration | 1. Asphalt pump: ZP230 insulation type high viscosity asphalt pump; 2. Asphalt pump drive motor: GM05 series high-torque plunger motor; 3. Hydraulic pump: F563 aluminum alloy gear pump; 4. Hydraulic system: imported proportional flow control valve; 5. Burner: G10 imported from Italy 6. Heating method: automatically heating by heat-conduction oil 7. Temperature control: AI microcomputer temperature controller; 8. Width of Spray : 1.2m ~ 4.5m, optional 6m precise triple overlapping Spray , 9. Spraying quantity control: manually adjust asphalt nozzle; 10. Asphalt pipeline compressed air cleaning function | |||

| Semi-intelligent configuration | 1. Asphalt pump: ZP230 insulation type high viscosity asphalt pump; 2. Asphalt pump drive motor: GM05 series high-torque plunger motor; 3. Hydraulic pump: F563 aluminum alloy gear pump; 4. Hydraulic system: imported proportional flow control valve; 5. Burner: G10 imported from Italy 6. Heating method: automatically heating by heat-conduction oil 7. Temperature control: AI microcomputer temperature controller; 8. Maximum width of Spray : 4.5 meters, optional 6 meters, precise three overlapping Spray , fully electric controln ozzle, 9. Sprinkler control: front and background potentiometer adjustment, digital display; 10. Asphalt pipeline compressed air cleaning function | |||

| Full intelligent configuration | 1. Asphalt pump: ZP230 insulation type high viscosity asphalt pump; 2. Asphalt pump drive motor: GM05 series high-torque plunger motor; 3. Hydraulic pump: F563 aluminum alloy gear pump; 4. Hydraulic system: imported proportional flow control valve; 5. Burner: G10 imported from Italy 6. Heating method: automatically heating by heat-conduction oil with selective heating function 7.temperature control: Germany Siemens temperature control module, computer temperature control 8. Maximum width of Spray : 4.5 meters, optional 6 meters, precise three overlapping Spray , fully electric control nozzle, 9. Sprinkling width is precisely controlled by computer: sprinkling quantity control: Germany Siemens PLC, intelligent control, sprinkling quantity and speed precise linkage, front touch screen control system. 10. Asphalt pipeline compressed air cleaning function | |||

| Full intelligent configuration imported Pump |

3. Hydraulic pump: Germany leisler plunger variable pump; 4. Hydraulic system: imported proportional flow control valve; 5. Burner: G10 imported from Italy 6. Heating method: automatically heating by heat-conduction oil with selective heating function 7.temperature control: Germany Siemens temperature control module, computer temperature control 8. Maximum width of Spray : 4.5 meters, optional 6 meters, precise three overlapping Spray , fully electric control nozzle, 9. Sprinkling width is precisely controlled by computer: sprinkling quantity control: Germany Siemens PLC, intelligent control, sprinkling quantity and speed precise linkage, front touch screen control system. 10. Asphalt pipeline compressed air cleaning function 11.spray volume 0.2 ~ 3 kg / , 28 sets of full electric nozzle, | |||

Our products enjoy a good reputation for the good quality!

The asphalt distributor is made up by chassis, asphalt tank, asphalt pump, optional conduction oil heating system, electronic control system and spraybar system, etc.

Major features:

1) Digital display meters and instruments to indicate speed of the vehicle and the asphalt pump rotation, as well as temperature of asphalt inside the tank.

2) Possesses heat preservation, conduction oil recycling heating, transportation, spray, pumping and discharge function, etc.

3) Nozzle controlled through pneumatic joint control operation of cylinder for opening and closing.

4) Cleaning system of compressed air

5) Hydraulic power take-off of chassis or auxiliary diesel engine for drive, heated with burner, optional conduction oil recycling system.

Technical Specifications:

Electronic control series

| Model | P3 | P4 | P6 | P8 | P10 | P12 | |

| Chassis | BJ1073 BJ1083 | BJ1103 BJ1120 | BJ1163 BJ5163 | SX1255 | ND1254 | ND1255 | |

| Capacity of asphalt tank (L) | 3000 | 4000 | 6000 | 8000 | 11000 | 12000 | |

| Max. distribution width(m) | 4 | 4.5 | 6 | 6 | 6 | 6 | |

| Distribution capacity (kg/m2) | 0.3-1.8 | 0.3-2.5 | 0.3-3 | 0.3-3 | 0.3-3 | 0.3-3 | |

| Distribution precision (%) | ≤2 | ||||||

| Heating mode | Diesel burner Heat capacity | ||||||

| 8×104Kcal/h | 8×104Kcal/h | 10×104Kcal/h | 15×104Kcal/h | 19×104Kcal/h | 19×104Kcal/h | ||

| Average Temp. Drop (°C/h) | ≤1 | ≤1 | ≤1 | ≤1.5 | ≤1.5 | ≤1.5 | |

Before sales:

1.Gratis professional consultant service,multi solution options, and most suitable product recommendation.

2.Special product design and manufacture based on your requirements.

3.Gratis professtional technology consultant,and detailed equipment working scheme as reference,for your special project.

After sales:

1.Gratis professional technology training,to train qualified operator for you.

2.Satisfying solution response in 2 hours after your quality feedback.

3.Equipment repair warranty(details in contract attachment),life time repair service(only free of charge of labour cost).

4.Save your individual product records.Asphalt distributor

Smart Intelligent control series

Major features:The distributor is made up by chassis, asphalt tank, asphalt pump, conduction oil

heating system, electrical and automatic control system and cleaning system, etc. with main units

made of the most up-to-date components in the international community, all-round control with

micro-computer, high distribution precision.

Three layers of overlapped cloth for spray, adjustable distribution capacity based on the

traveling speed, totally operable in the cabin for distribution

Separate control with computer at each spraybar of adjustable width.

Two control systems in the control process for the whole truck (cabin and rear operating platform) to ensure reliable and successful asphalt distribution.

All-round heating of pump, spraybar and tank with conduction oil or separate heating.

Optional radar speed measurement system

Safe and reliable conduction oil heating system for fully automatic control

| Model | S4 | S7 | S8 | S10 | S12 | |

| Chassis | BJ1103 BJ1120 | BJ5163 | SX1165 | SX1255 | ND1254 | |

| Capacity of asphalt tank (L) | 4000 | 6800 | 8000 | 10000 | 12000 | |

| Max. distribution width(m) | 4.5 | 6 | 6 | 6 | 6 | |

| Distribution capacity (kg/m2) | 0.3-2.5 | 0.3-3 | 0.3-3 | 0.3-3 | 0.3-3 | |

| Heating Mode | Diesel Burner Heat capacity | |||||

| 8×104Kcal/h | 12×104Kcal/h | 14×104Kcal/h | 19×104Kcal/h | 19×104Kcal/h | ||

Cell :+8615271357675

Related Products

SUCCESS CASES

More >>- 2024-04-0910 Units T14 ISOTank Container For Hydrofluoric Acid Export to India

10 Units T14 ISOTank Container For Hydrofluoric Acid Export to India 20FT TANK CONTAINER (EMPTY AND NEW TANKS) 20 FT TANK CONTAINER FOR HYDROCHLORIC ACID UN1789 HCL, HYDROFLUORIC ACID UN1790 HF ACID CARON STEEL AND LINED WITH 16MM LLDPE TANKS CAPACITY 21 KL FOR ROAD INLAND MOVEMENTS

- 2023-12-226 pcs Metal Alky T21 UN3394 UN3399 Portable Tank TEAL DEAC MAO to SGP

6 pcs Metal Alky T21 UN3394 UN3399 Portable Tank TEAL DEAC MAO to SGP Max. gross weight : 4000 kg Tare : 1050 kg Payload : 2950 kg Portable Tank instruction : T21 ADR/RID tank code : N/A Special provisions : TP2 TP7 TP36 TP41 Model : KS1880-T21 ISO size/type code : N/A Type : UN Portable Tank Dimensions : 1148(E.D) x2128 (L) x1388 (H) mm Nominal capacity : 1880 L Measured capacity : 1880 L at 20°C Maximum allowable working pressure : 14 bar Test pressure : 21 bar APPROVALS ADR/RID: F/9151/BV/23 IMDG: F/BV/23/194-T21 US DOT: UN Portable Tank TIR*: GB/C 26839 BV/2023 SUBSTANCES SUITABLE FOR TRANSPORT: In accordance with the requirements of the applicable regulations and the construction of the tank and its equipment. (Substances not compatible with the tank and/or its accessories are excluded for transport) UN3394 & UN3399

- 2024-01-29Customized Hydrochloric Acid HCL Tank Container Lined PE 24m3 for Trailer Mounted to Vietnam

Customized Hydrochloric Acid HCL Tank Container Lined PE 24m3 for Trailer Mounted to Vietnam TANK CONTAINER VOLUME 24M3 STEEL SHEET 5MM, HEAD 6MM,Lined LLDPE 16mm for Hydrochloric Acid, Sulfuric Acid Transport 3 CHAMBERS HS CODE: 7309.00

- 2023-02-226 units Metal Alky C480 Portable Tank TEAL DEAC Cylinder for Singapore

6 units Metal Alky C480 Portable Tank TEAL DEAC Cylinder for Singapore 360 DEG. ROTATABLE TOP FLANGE VALVE (KV-MTFF DN15 PN 40), 360 DEG. ROTATABLE TOP FLANGE VALVE (KV-MTFE DN20 PN 40) K4430 Gaskets

- 2023-12-246 Units 40KL 44KL 40FT ISO Steel Lined PE Dilute Sulfuric Acid Tank Container To Kazakhstan

6 Units 40KL 44KL 40FT ISO Steel Lined PE dilute sulfuric acid Tank Container to Kazakhstan40FT Tank Container PE Lined TankUsed to contain: HCl (max 35%), NaOH (max 50%), PAC (max 17%),H2SO4(max 94%) etc…Sulphuric Acid Tank Capacity: 40,000 Liters;44,000 LitersSteel sheet 6mm, head 6mmLiner thickness: 16mm PE01p

- 2023-09-222 Sets HOWO Offroad AWD 6x6 Mixing And Charging ANFO Explosive Trucks Delivery

2 Sets HOWO Offroad AWD 6x6 Mixing And Charging ANFO Explosive Trucks Delivery

- 2023-09-1510 Units Hydrochloric Acid HCL PE LINED ISO Tank Containers to Vietnam

10 Units Hydrochloric Acid HCL PE LINED ISO Tank Containers to Vietnam 20FT Tank Container PE Lined Tank Used to contain: HCl (max 35%), NaOH (max 50%), PAC (max 17%),H2SO4(max 94%) etc… Tank Capacity: 21,900 Liters Steel sheet 6mm, head 6mm Liner thickness: 16mm PE

- 2023-08-1417m3 , 22m3 Lined PE Tank Container for Hydrochloric Acid HCL to Vietnam

17m3 , 22m3 Lined PE Tank Container for Hydrochloric Acid HCL to Vietnam 20FT TANK CONTAINER TANK VOLUME/ STEEL THICKNESS 22M3/ 6MM (SOC / EMPTY AND NEW TANKS) BRAND: DONG RUNZE MODEL: DRAU2308018 STORAGE TANK CONTAINER TANK FOR HCL CARGO TRUCK TANK VOLUME/STEEL THICKNESS:17M3/ 6MM ( EMPTY AND NEW TANKS) BRAND: DONG RUNZE MODEL: DTA5260 HS CODE : 7309000000

- 2023-07-104 Sets Polyethylene Lined Steel Offshore T14 Tanks For Hydrochloric Acid Transport to Kazakhstan

4 Sets Polyethylene Lined Steel Offshore T14 Tanks For Hydrochloric Acid Transport to Kazakhstan Marks DTAU2305012 DTAU2305028 DTAU2305033 DTAU2305049

- 2022-12-2780Units Metal Alky C480 UN Portable Tank T21 TEAL Cylinders to USA

80Units Metal Alky C480 UN Portable Tank T21 TEAL Cylinders to USA 80Units UN T21 Portable Tank Container 1880L Cylinder For TEAL Metal Alkyls UN3394 UN3399 to USA Adr/Rid Organometallic Substance, Liquid, Water- Reactive C-430 Saddle Type Portable Tank , tank capacity 1630L C-480 Saddle Type Portable Tank, tank capacity 1880L C-1980 TEAL TMGa ,TEGa,TMIn, TMAl DEAC Metal Alky C-1980 T21 Metal Alky 7495L

- 2023-04-056 Sets Polyethylene Lined Steel Tanks 6600Gallon For Hydrochloric Acid Storage Transport Hydrochloric Acid (HCl) to SAU Chemical Factory

6 Sets Polyethylene Lined Steel Tanks 6600Gallon For Hydrochloric Acid Storage Transport Hydrochloric Acid (HCl) to SAU Chemical Factory This the 4th LOT HCL ,NaCLO Tanks For this SAU Chemical Facttory . The 1 st Order date will go back to Date 13-1-2021. CAST IRON STORAGE TANK FOR CHEMICAL MATERIALS STORAGE TANK CAPACITY: 25M3 HS CODE:7309000000

- 2023-03-063 Sets Lined PE Tanks 6604Gallon For Storage Transport Sodium Hypochlorite to Saudi Arabia

3 Sets Lined PE Tanks 6604Gallon For Storage Transport Sodium Hypochlorite to Saudi Arabia FROM WUHAN PORT CHINA TO DAMMAM, SAUDI ARABIA BY SEA. + Port of loading : WUHAN PORT + Port of unloading :DAMMAM CAST IRON STORAGE TANK FOR CHEMICAL MATERIALS STORAGE TANK CAPACITY: 25M3 HS CODE:730900 10.2x2.1x2.5*3 160.65cbm 3X40HQ

- 2023-01-054PCS Power Take-off PTO FOR JMC TRANSMISSION MODEL DN3-7003-EC 6MT1420 to URUGUAY

4PCS Power Take-off PTO FOR JMC TRANSMISSION MODEL DN3-7003-EC 6MT1420 to URUGUAY Sdq51/65 (Gearbox Power Take off For ISUZU QINGLING Transmission DN3-70030-E0, 6MT1420 PTO Assembly) HWP-G32/65CHQ ,32/65 PQ1

- 2023-02-0812PCS PTO Wanliyang Transmission Power Take-off For WLY6T40 WLY6TS40 to Mexico

12PCS PTO Wanliyang Transmission Power Take-off For WLY6T40 WLY6TS40 to Mexico 1 PC SDQ211/60LGQ1 PTO FOR 6DS60T-D TO SAUDI ARABIA

- 2022-12-282 Units Righ Hand Drive Shacman F3000 Hydro Excavators Truck Combined Vacuum Sewer Jetting to Suva Port Fiji

2 Units Righ Hand Drive Shacman F3000 Hydro Excavators Truck Combined Vacuum Sewer Jetting to Suva Port Fiji Shacman F3000 Hydro Excavators Truck Sewer Jet Suction Units (RHD 13500L Sewage+4000L Clean Water ) PTO, transmission shaft, vacuum pump, tanker, hydraulic system and jetting pipe system. Combined Sewer Suction & Jetting Unit SZW Aluminium Alloy Liquid Water Ring Compressor Vacuum Pump XW-2800 VAC Flow 2800 M³/h ,1648 Cfm 46.7M3/min 75KW